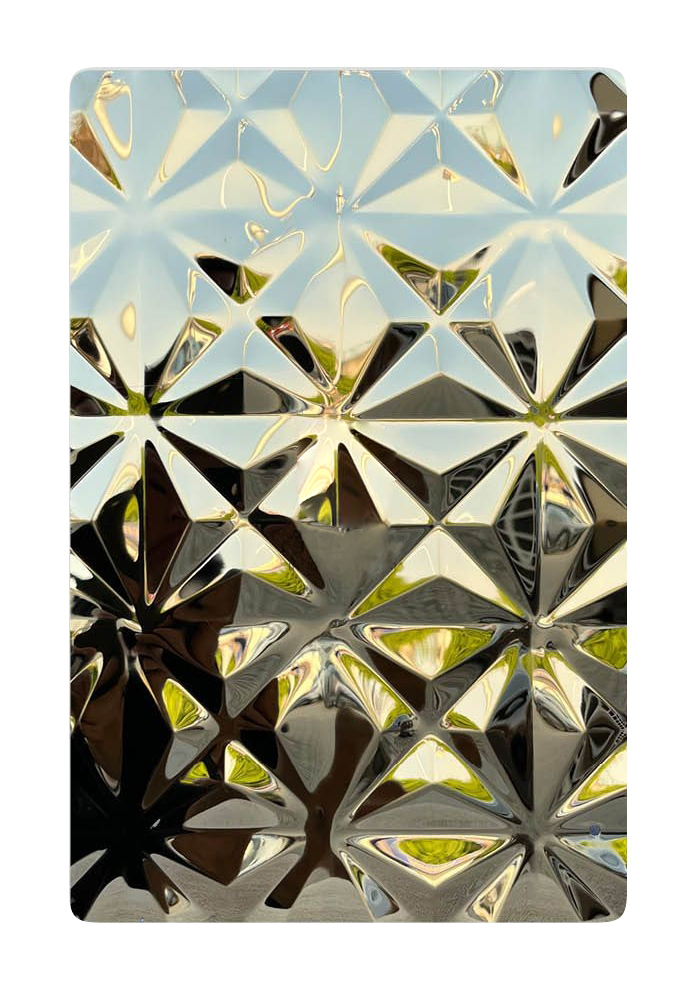

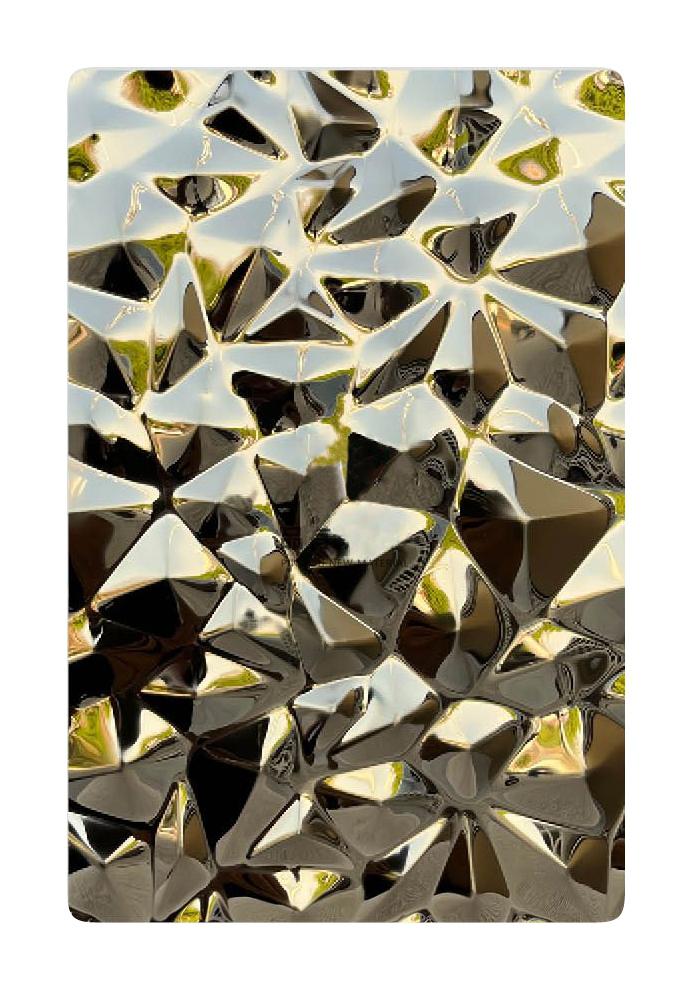

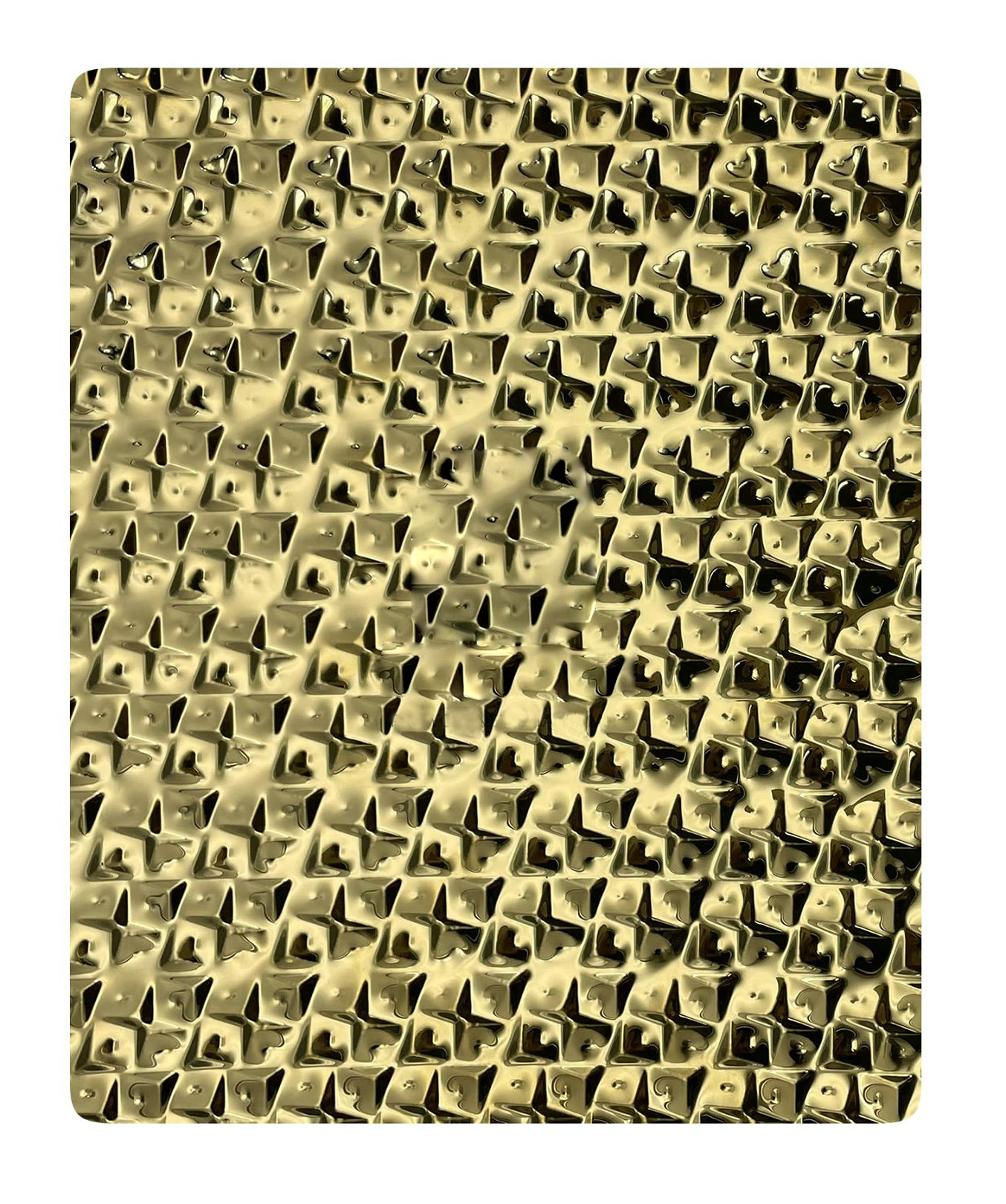

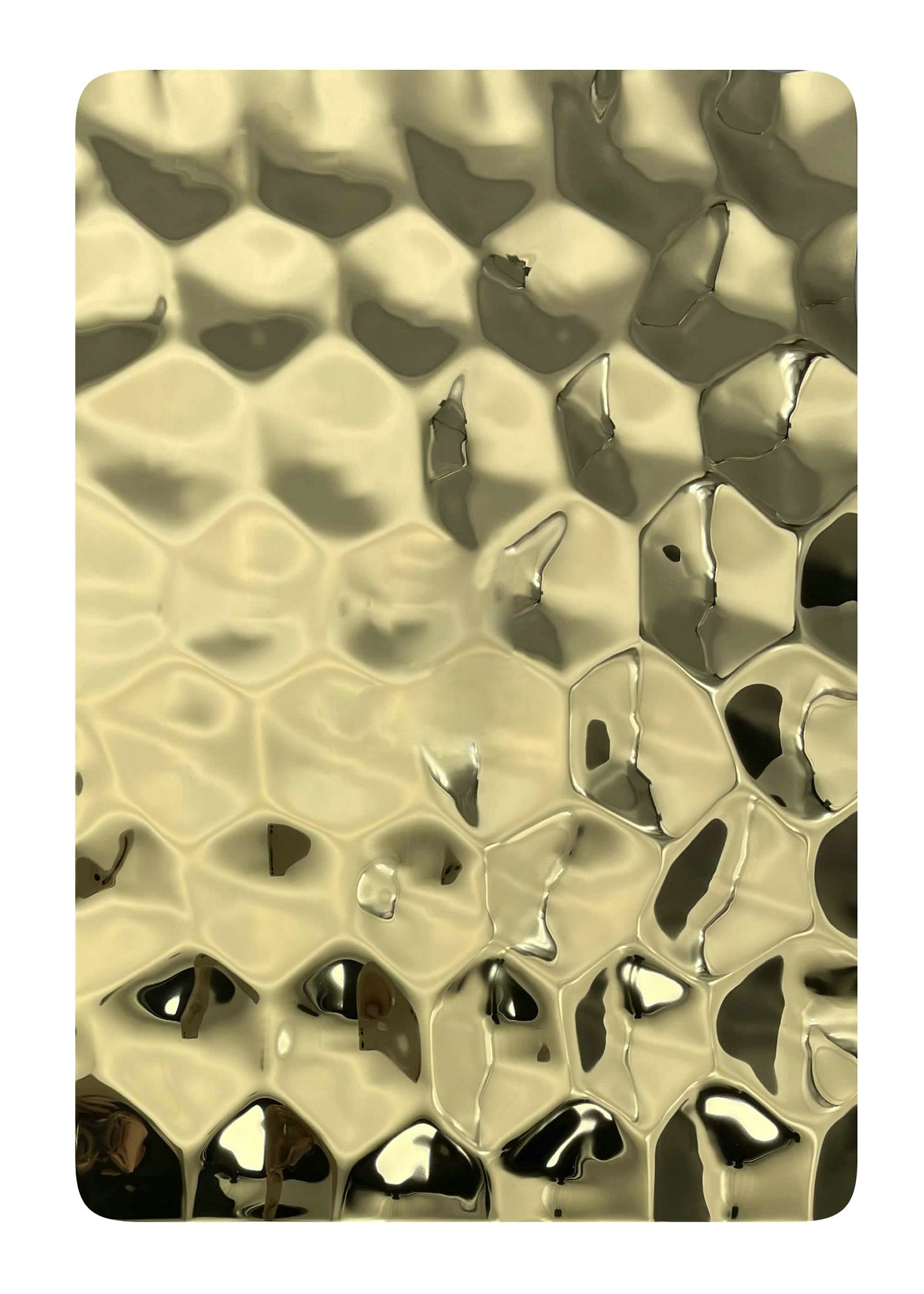

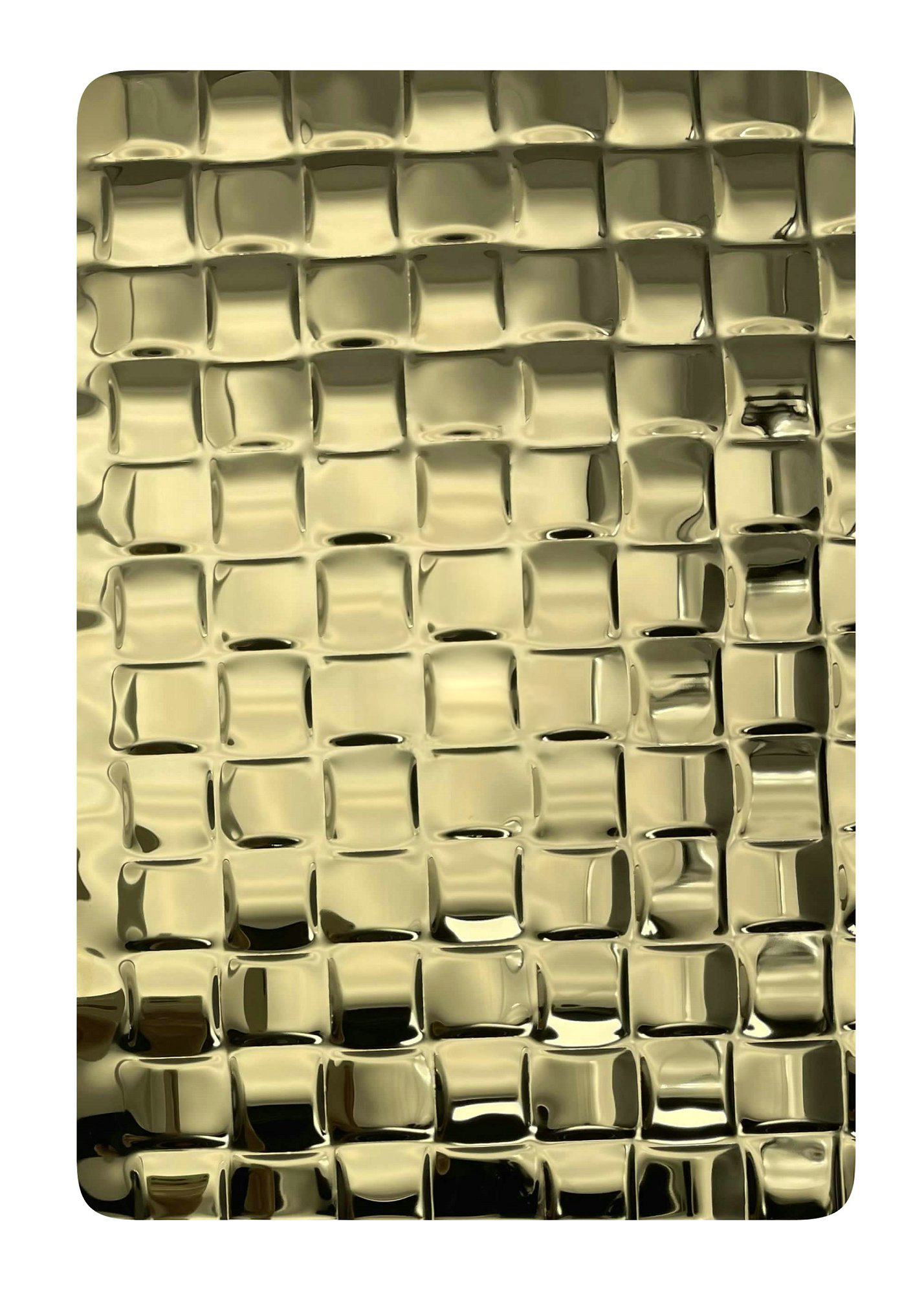

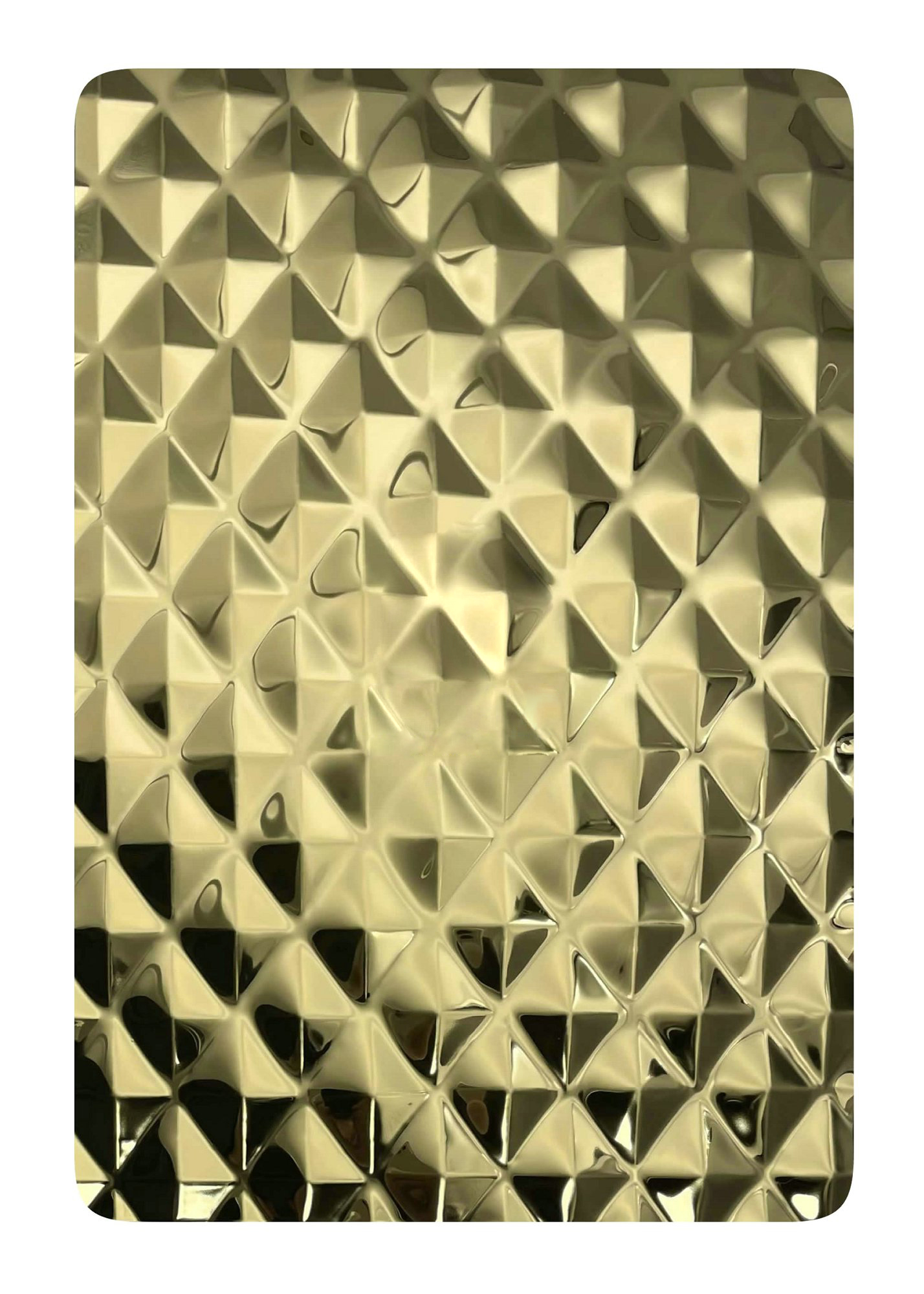

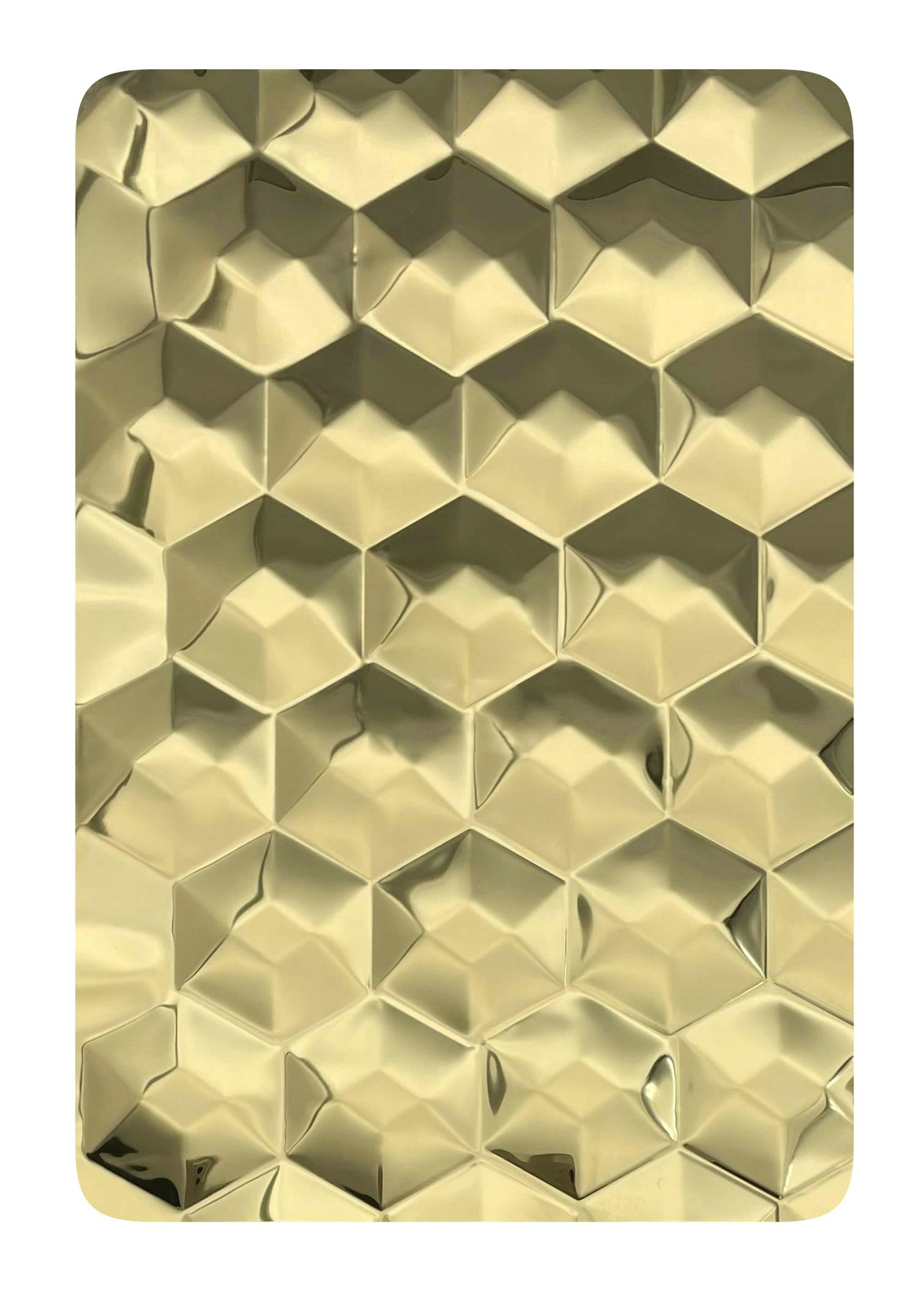

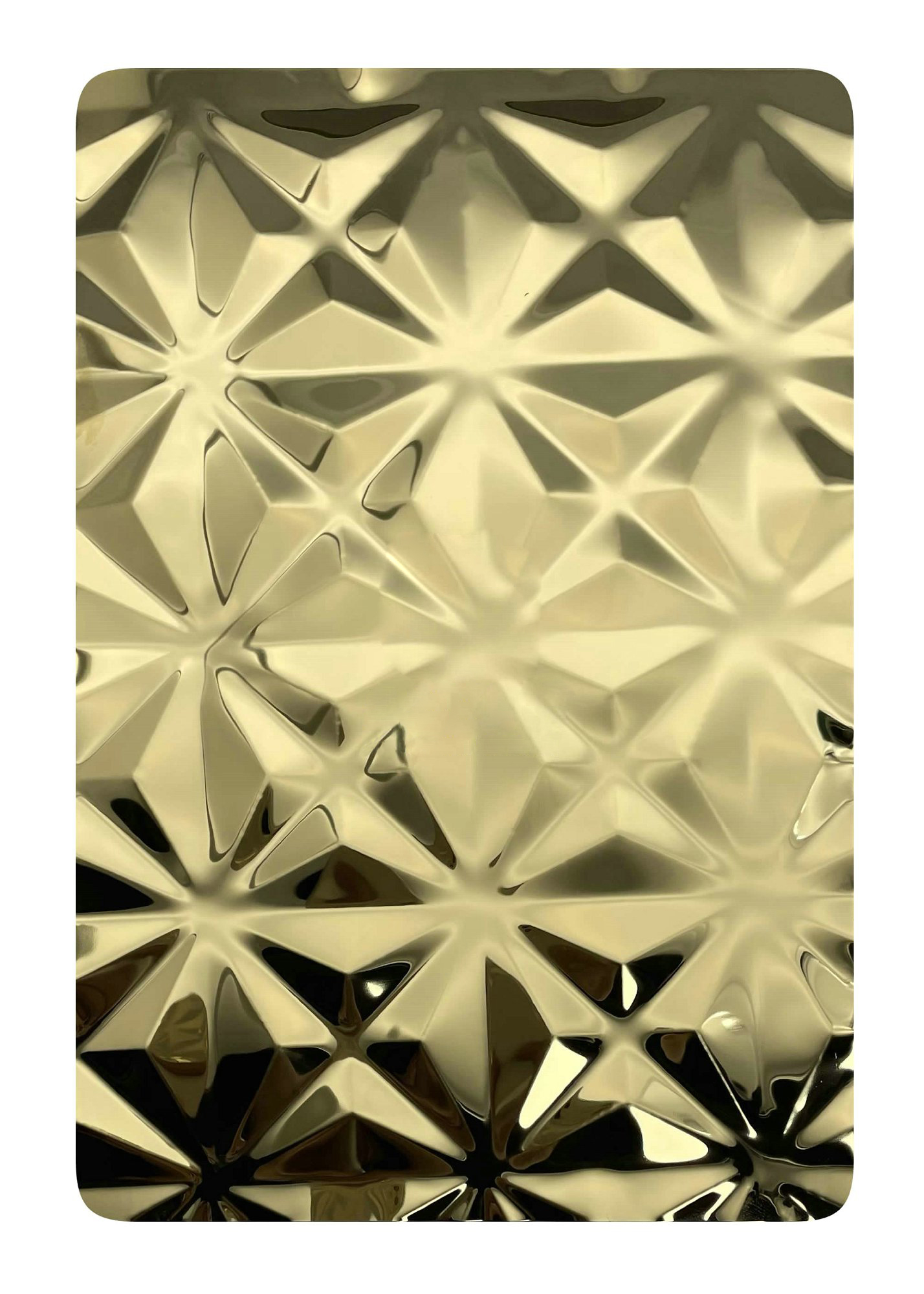

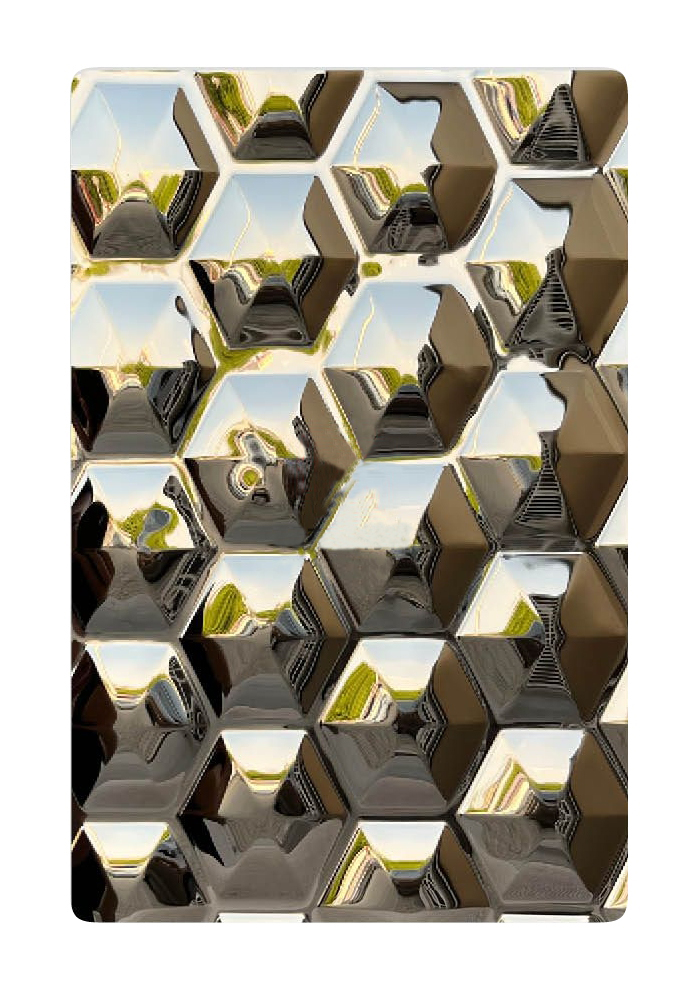

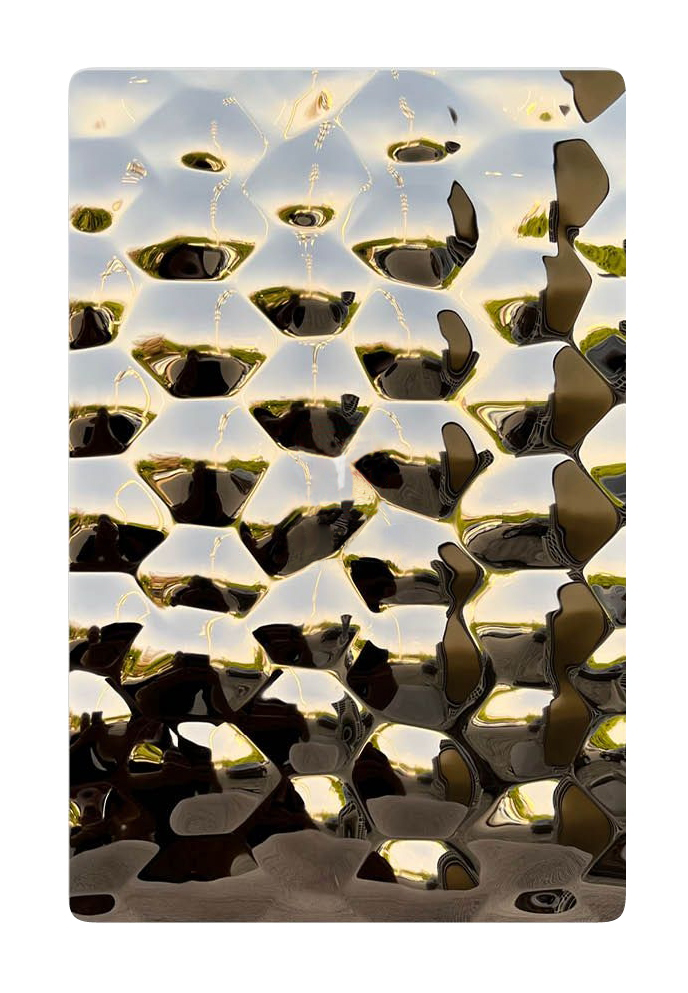

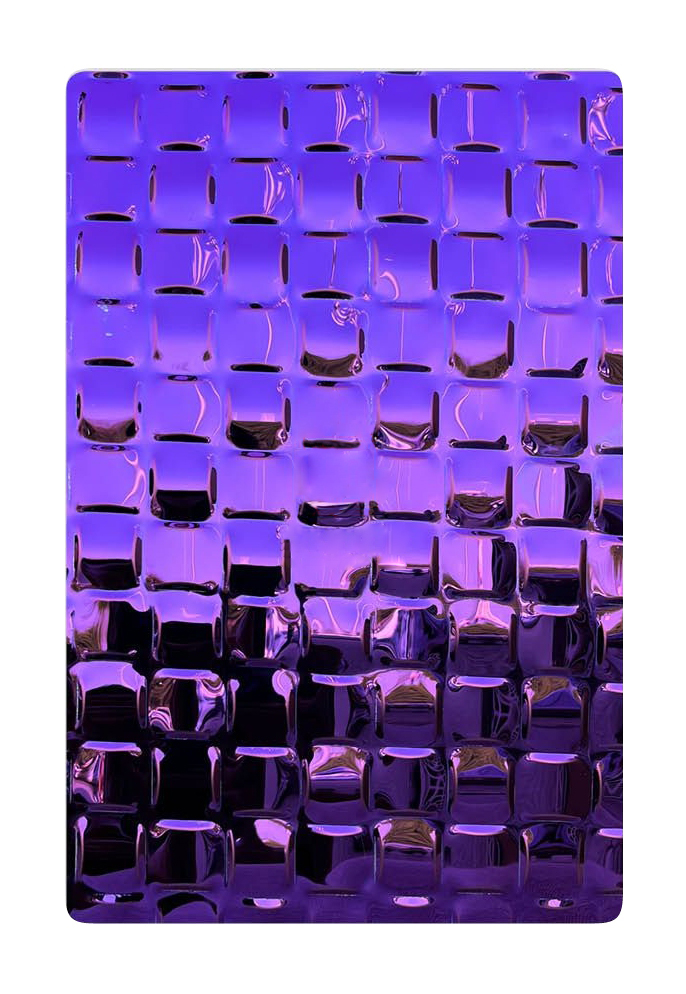

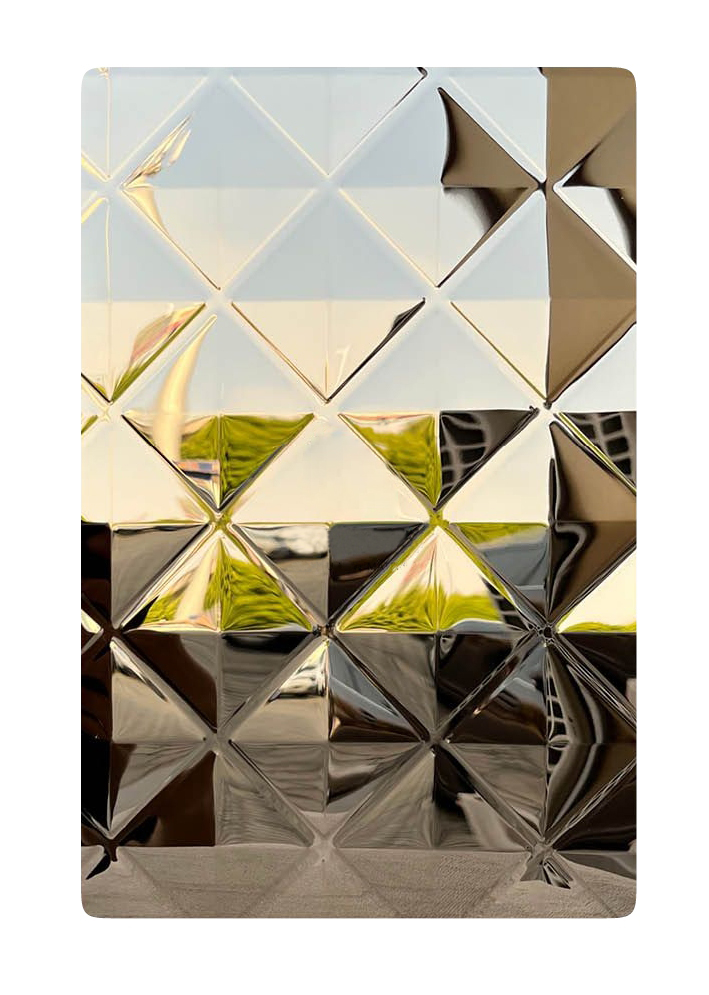

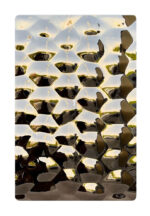

Processing & Characteristics — Stamped Stainless Steel Sheets

المواد

SS 304: Excellent corrosion resistance and mechanical strength, suitable for both decorative and structural use.

SS 316L: Superior resistance to pitting and chemical corrosion, ideal for outdoor or marine environments.

SS 201: Economical choice with good hardness and formability, suitable for interior decorative applications.

المعالجة

Material Preparation: High-quality stainless steel sheets (SS 304, SS 316L, SS 201) are carefully selected based on the required pattern, strength, and surface finish.

Stamping Process:

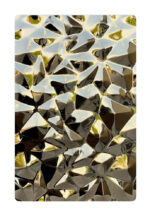

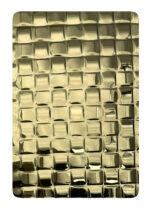

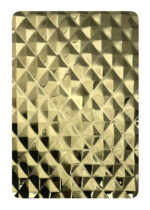

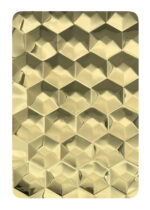

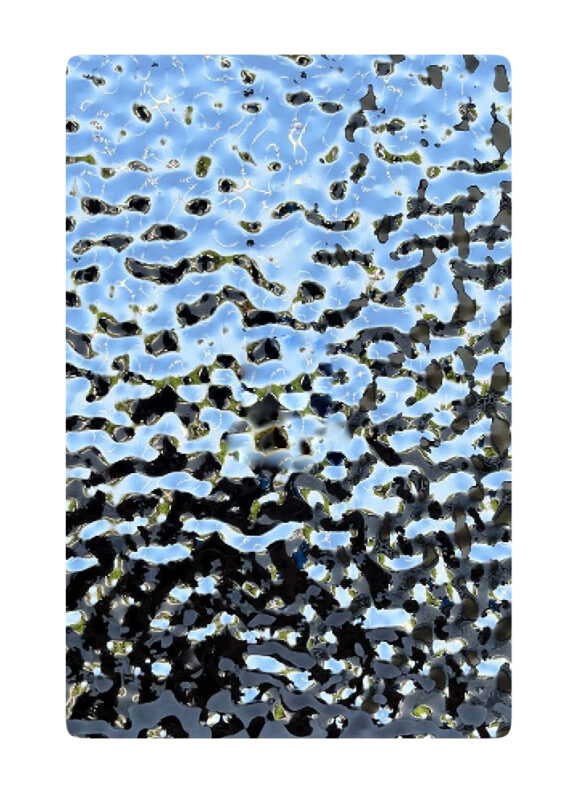

The stainless steel sheets are processed through precision stamping molds that press decorative patterns—such as linen, diamond, or custom textures—onto the surface.

This process enhances visual appeal while increasing the sheet’s rigidity and strength.

Cleaning and Surface Treatment: After stamping, sheets are cleaned and optionally treated with protective coatings like anti-fingerprint or PVD finishes for improved durability and easy maintenance.

Quality Inspection: Each sheet is checked for uniform pattern depth, sharpness, and surface integrity to ensure premium appearance and performance.

الخصائص

-

Distinctive 3D Texture: The stamped patterns create a unique visual and tactile effect that enhances architectural aesthetics.

-

Enhanced Strength: The stamping process increases stiffness and resistance to deformation.

-

Durable and Corrosion-Resistant: Maintains stainless steel’s inherent corrosion resistance, suitable for long-term use.

-

Scratch and Fingerprint Resistance: Textured surface effectively conceals scratches, fingerprints, and minor wear.

-

Versatile Applications: Widely used in elevator cabins, wall panels, ceilings, door frames, furniture, and architectural decoration.