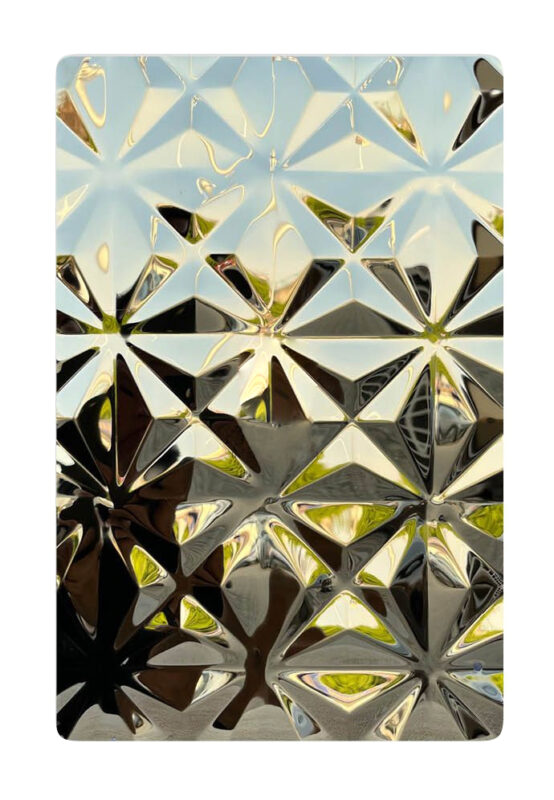

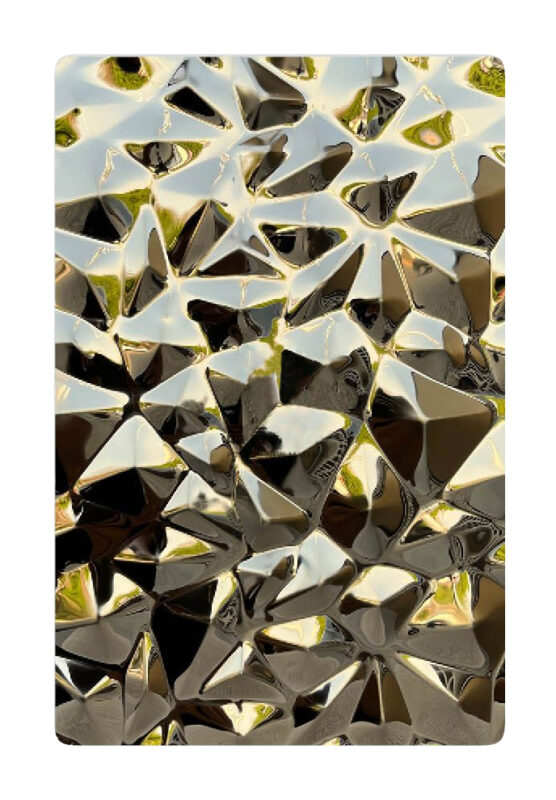

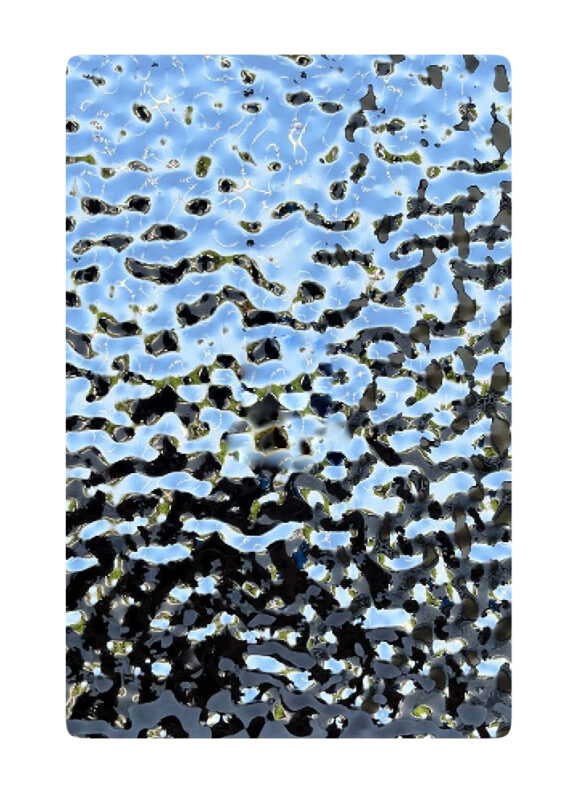

Materials

- SS 304: Provides excellent corrosion resistance and durability, widely used for both decorative and functional applications.

- SS 316L: Offers superior resistance to corrosion, particularly in marine or chemical environments.

- SS 201: A cost-effective option with good mechanical strength, ideal for decorative purposes in less demanding environments.

Processing

- Material Preparation: High-quality stainless steel sheets (SS 304, SS 316L, SS 201) are selected to meet the desired performance and aesthetic requirements.

- Bead Blasting:

- Stainless steel sheets are treated with fine glass beads under high pressure using advanced blasting equipment.

- This process creates a uniform, matte surface with a smooth and non-reflective finish.

- Cleaning: Post-blasting, the sheets are cleaned to remove any residue and ensure a spotless surface.

- Optional Surface Coating: Additional protective coatings, such as anti-fingerprint or PVD finishes, can be applied for enhanced durability and ease of maintenance.

- Quality Inspection: Each sheet undergoes rigorous testing for surface uniformity, texture consistency, and overall quality to meet customer specifications.

Characteristics

- Elegant Matte Finish: The bead-blasting process creates a refined, non-reflective surface that enhances the visual appeal.

- Durability: Resistant to scratches, fingerprints, and daily wear, suitable for high-traffic and industrial applications.

- Corrosion Resistance: Retains the inherent rust resistance of stainless steel, ensuring longevity in various environments.

- Low Maintenance: The matte texture hides smudges and dirt, making it easy to clean and ideal for hygiene-sensitive areas.

- Versatility: Widely used in elevators, kitchen appliances, interior decor, wall panels, signage, and architectural projects.

- Customizability: Available in various thicknesses, sizes, and finishes to meet specific project requirements.