Materials

- SS 304: Known for its excellent corrosion resistance and durability, making it an ideal base for PVD coating.

- SS 316L: Offers superior corrosion resistance, particularly in harsh or marine environments, for long-lasting PVD finishes.

- SS 201: A cost-effective option with good mechanical properties, suitable for indoor decorative applications.

Processing

- Material Preparation: High-quality stainless steel sheets (SS 304, SS 316L, SS 201) are cleaned and pre-treated to ensure a flawless base.

- PVD Coating Process:

- Physical Vapor Deposition (PVD) technology is used to apply a thin, durable coating to the stainless steel surface.

- The process involves vaporizing metallic materials under a vacuum and depositing them onto the surface, creating a highly durable and decorative finish.

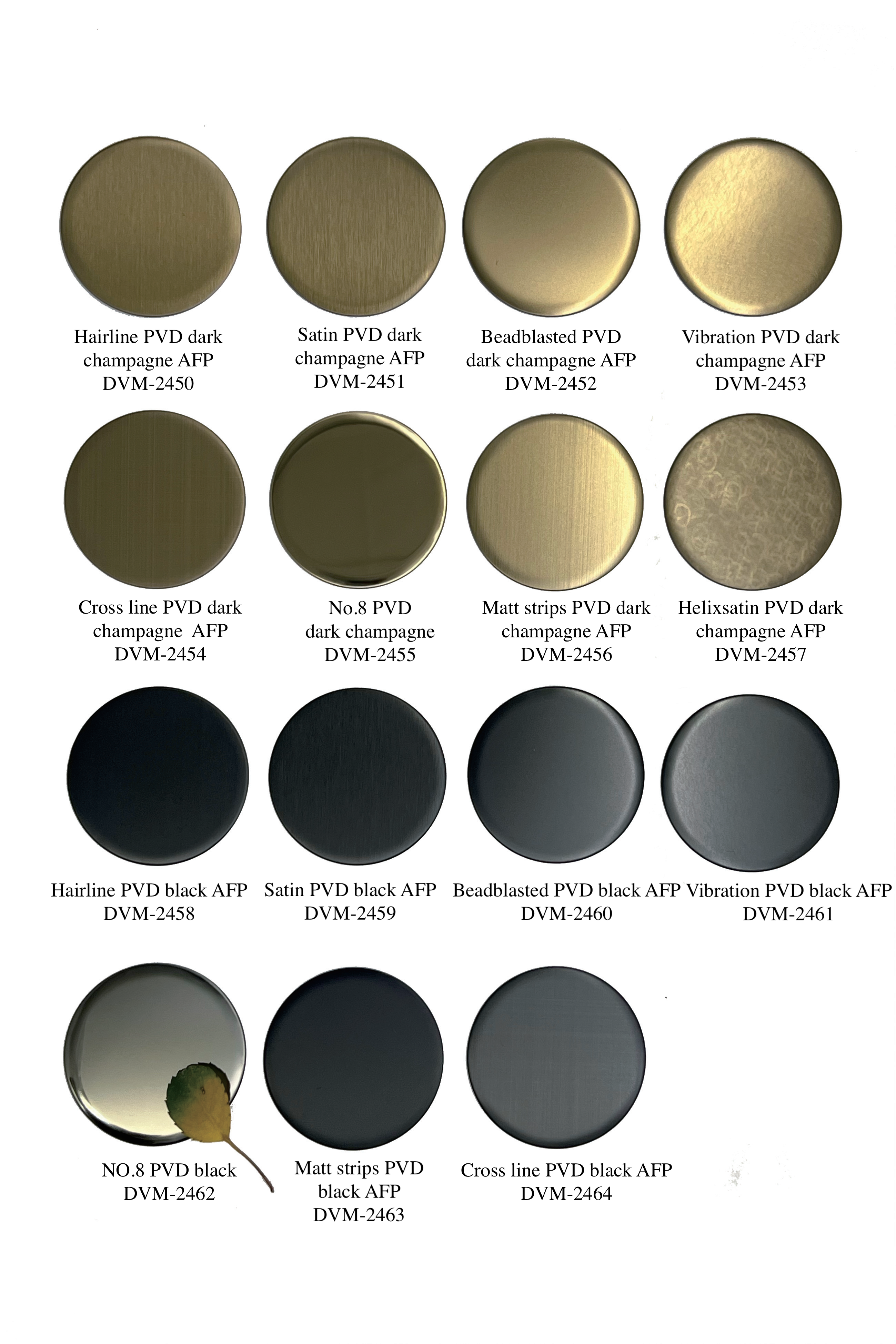

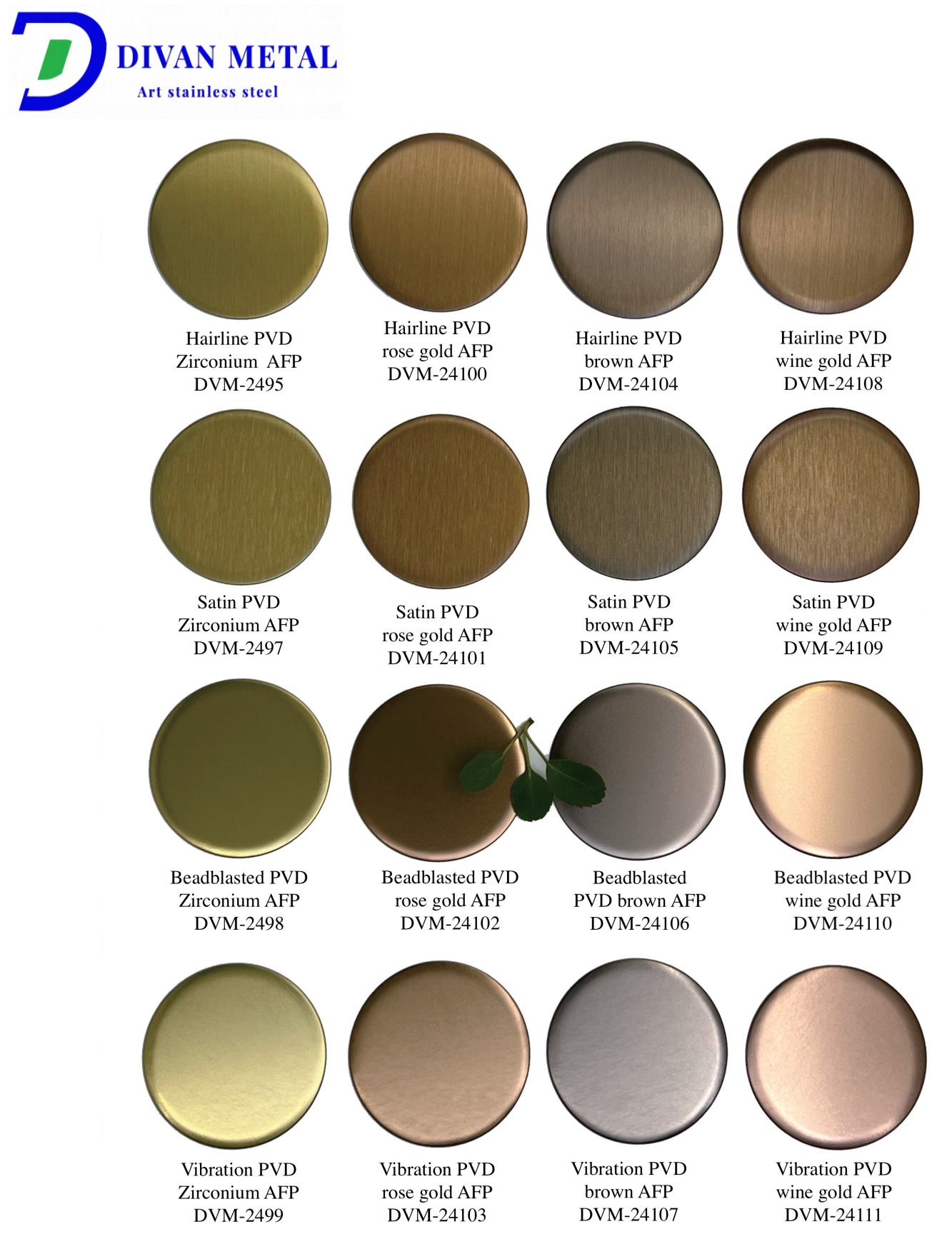

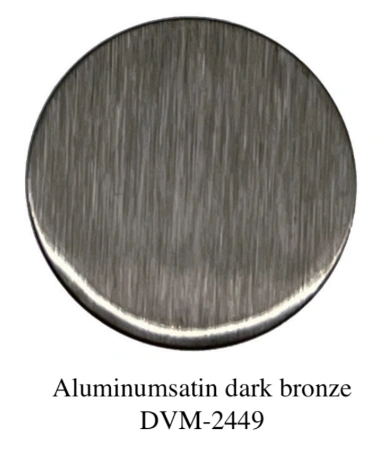

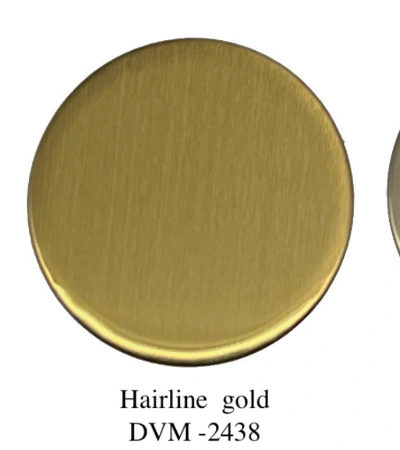

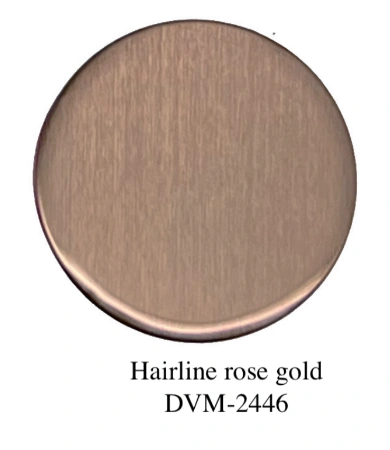

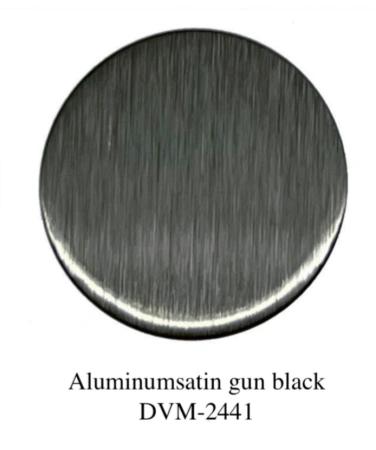

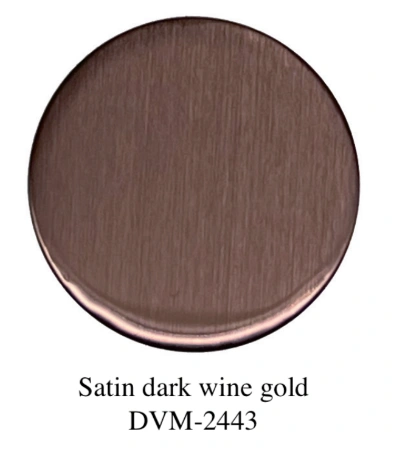

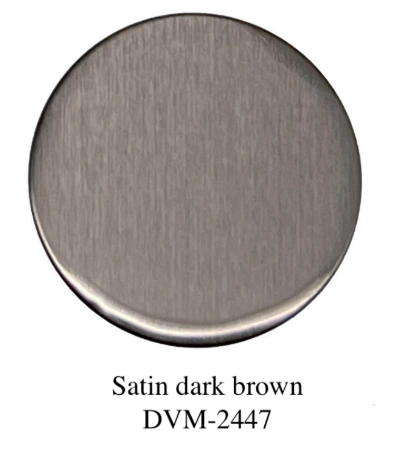

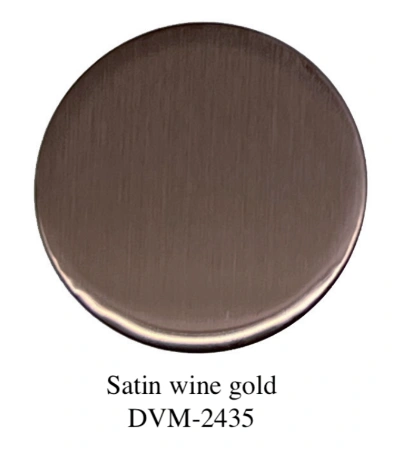

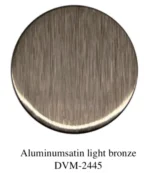

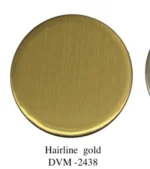

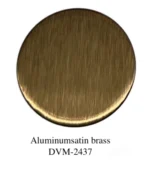

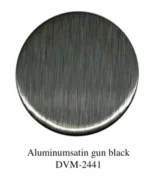

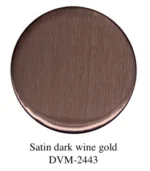

- Настройка цвета: A wide range of colors is available, including gold, rose gold, black, bronze, blue, and rainbow finishes.

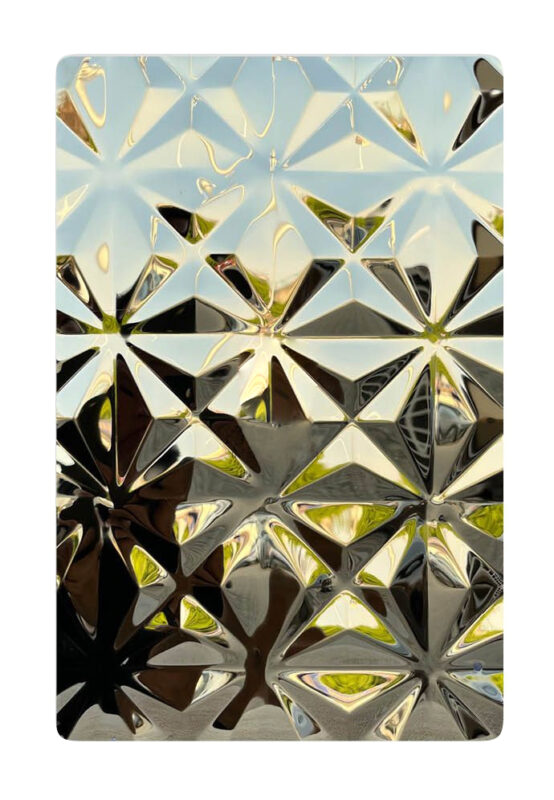

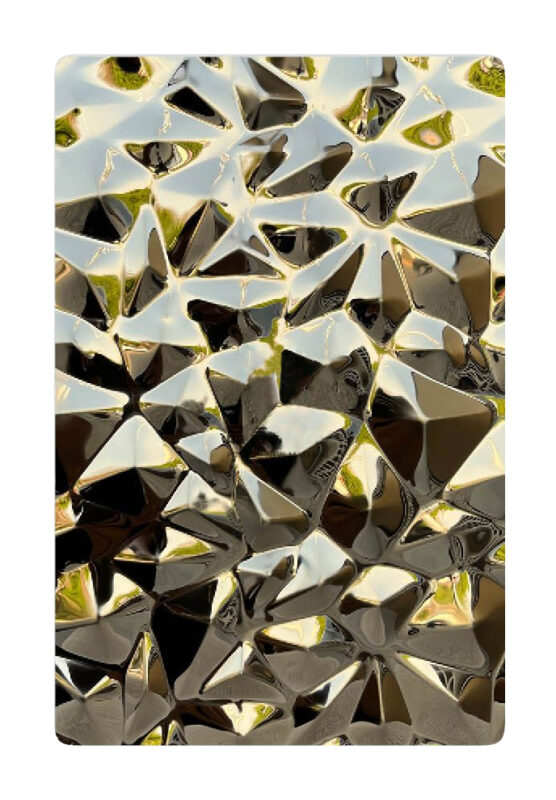

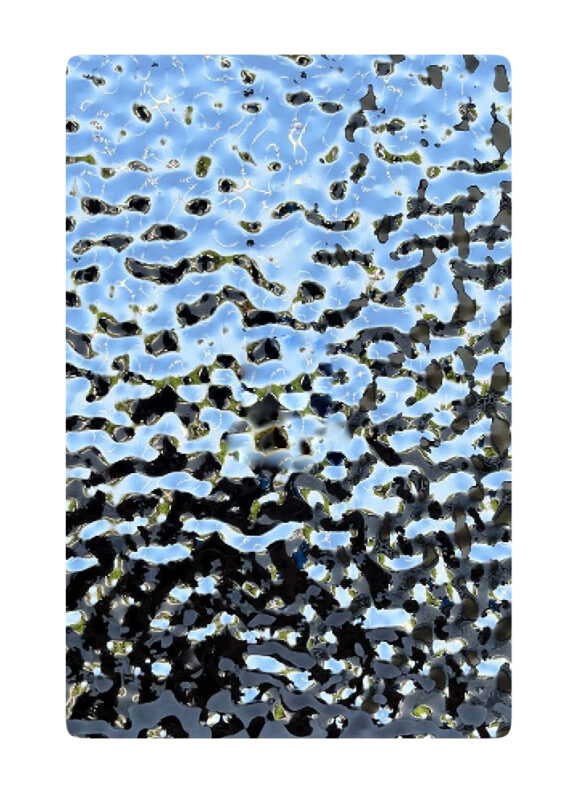

- Surface Finishing: The coated sheets can be further finished with mirror, brushed, matt, or etched textures for enhanced design flexibility.

- Quality Control: Each sheet undergoes stringent testing for coating adhesion, color uniformity, and surface quality to meet high standards.

Characteristics

- Luxurious Appearance: PVD coating provides a vibrant, metallic finish with a sleek and modern aesthetic.

- Durability: Highly resistant to scratches, corrosion, and fading, ensuring long-term performance in various environments.

- Eco-Friendly Process: PVD coating is environmentally friendly, as it produces no hazardous by-products or emissions.

- Low Maintenance: Easy to clean and resistant to smudges and fingerprints, making it ideal for high-visibility applications.

- Versatility: Perfect for elevator interiors, wall panels, signage, furniture, kitchen appliances, and architectural cladding.

- Customizable: Available in various colors, patterns, and textures to meet diverse design and functional needs.