Materials

- SS 304: Known for its excellent corrosion resistance and versatility, ideal for brushed or matt finishes in decorative and functional applications.

- SS 316L: Provides superior resistance to corrosion, suitable for harsh environments or outdoor installations.

- SS 201: A cost-effective option with good strength, commonly used for interior decorative purposes.

Processing

- Material Selection: High-quality stainless steel sheets (SS 304, SS 316L, SS 201) are selected to ensure the desired performance and aesthetics.

- Surface Preparation: The sheets are cleaned and pre-treated to remove surface impurities, ensuring a uniform finish.

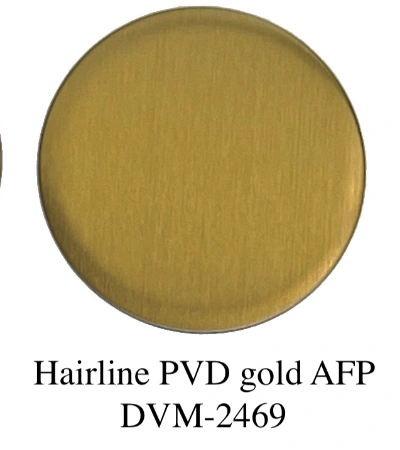

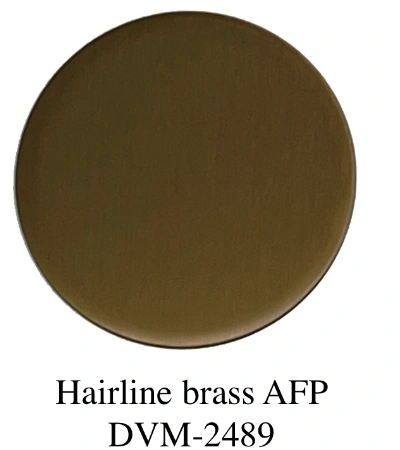

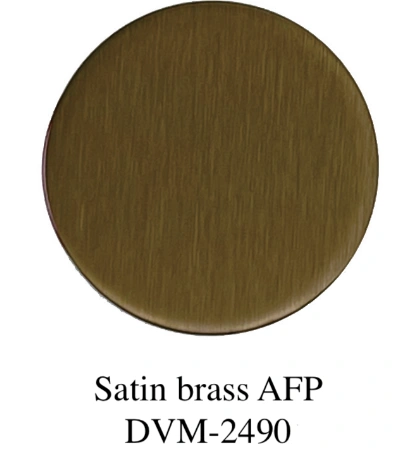

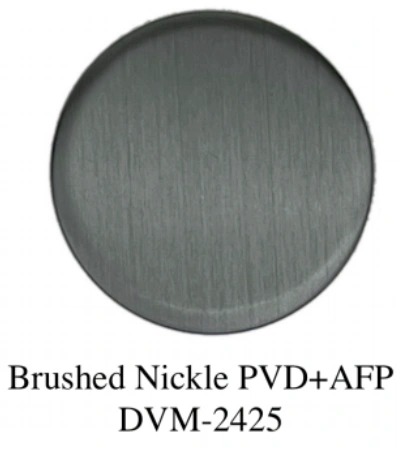

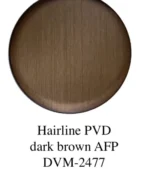

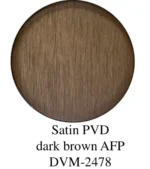

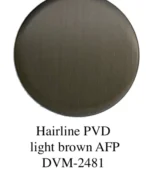

- Brushing Process:

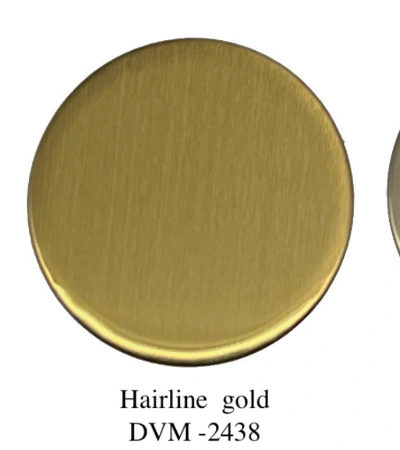

- Specialized abrasive belts or brushes are used to create a consistent linear texture for a brushed finish.

- For matt finishes, fine-grit abrasives are used to achieve a smooth, low-gloss surface.

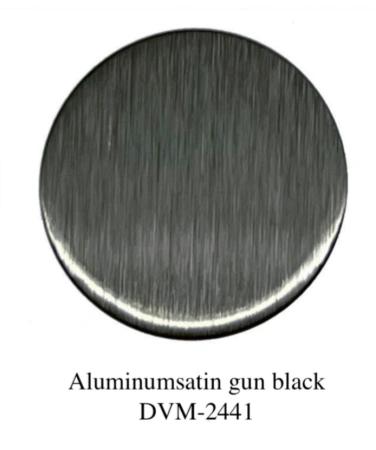

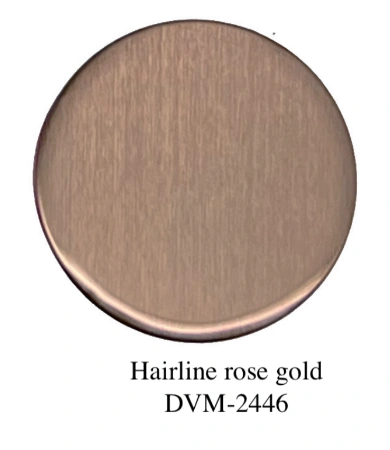

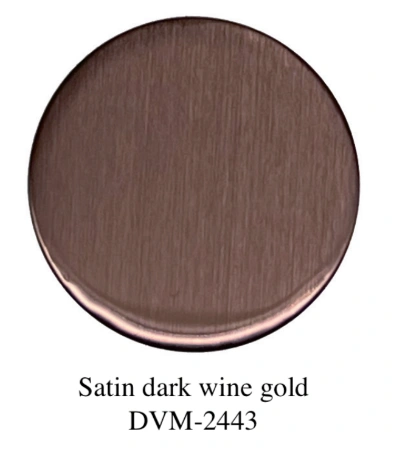

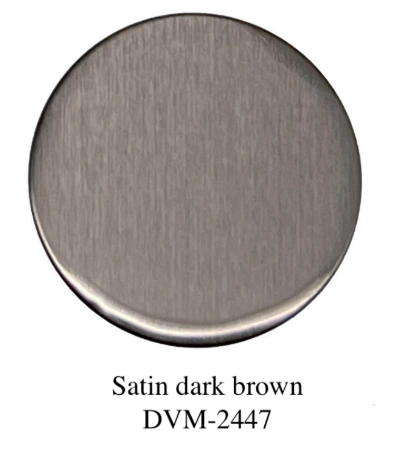

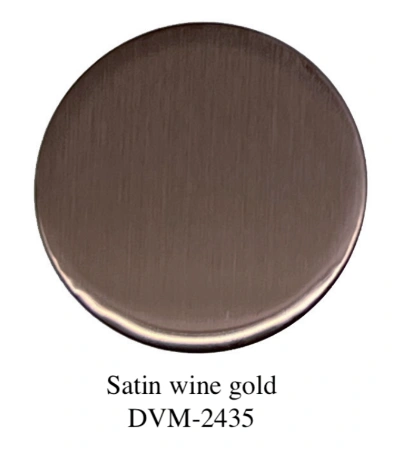

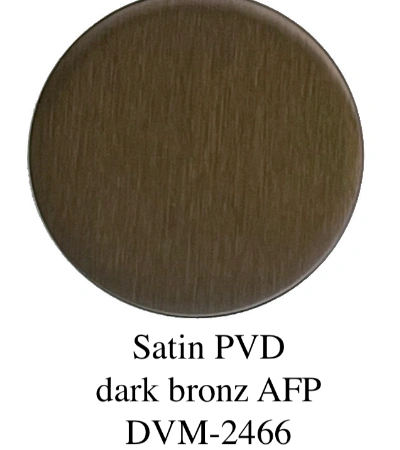

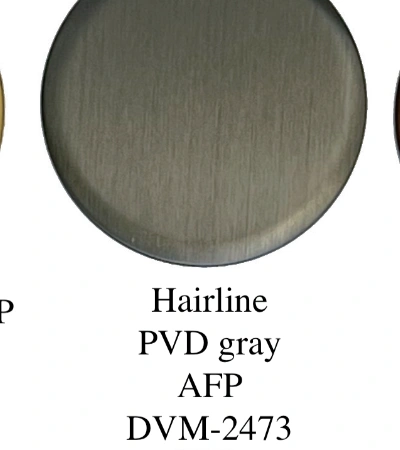

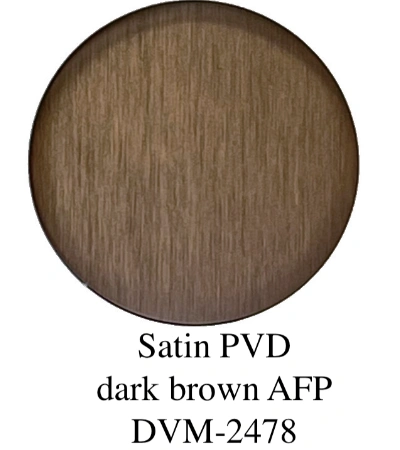

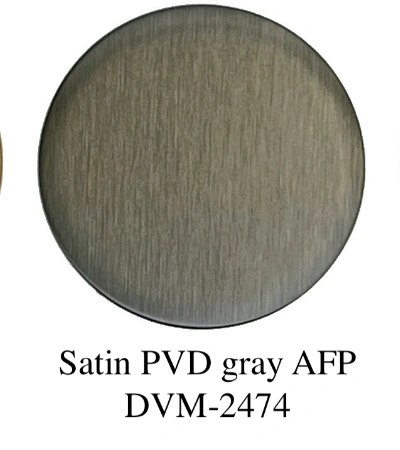

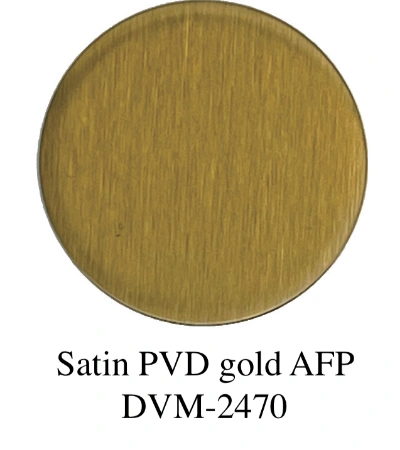

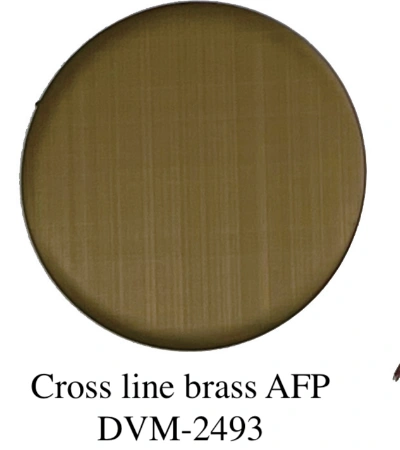

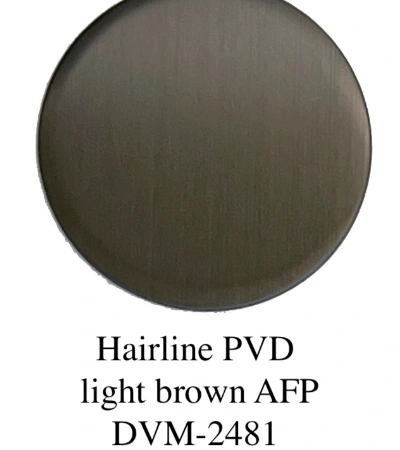

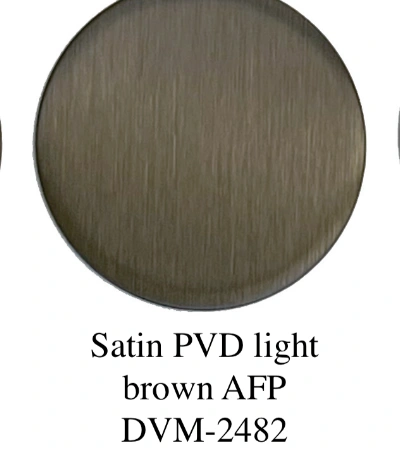

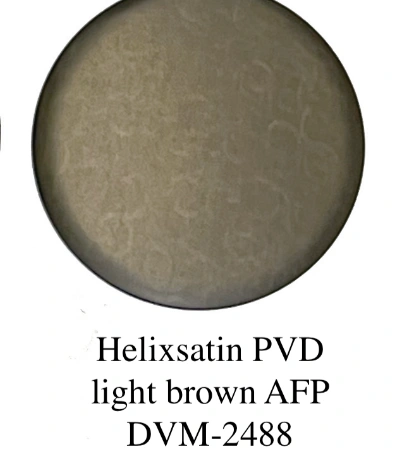

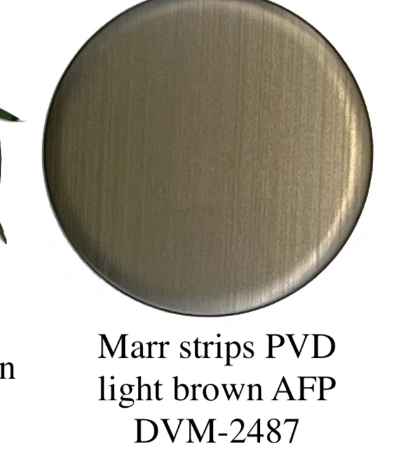

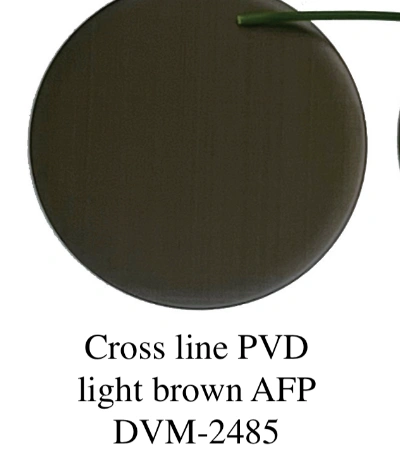

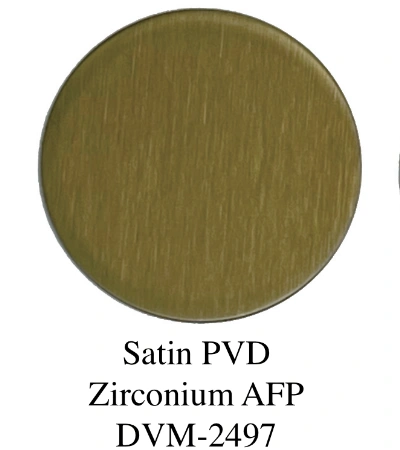

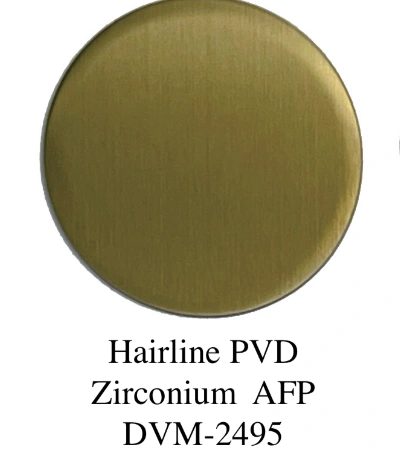

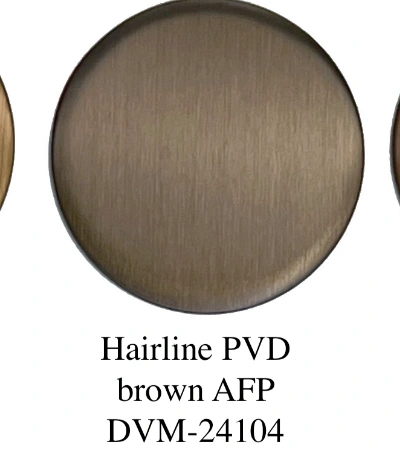

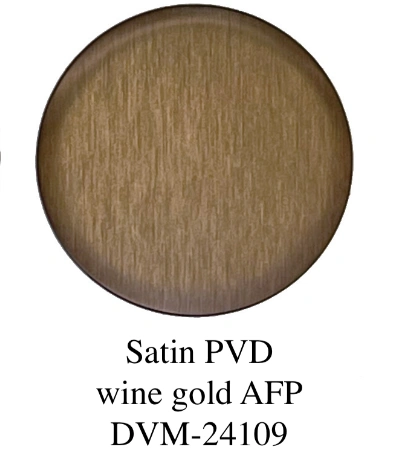

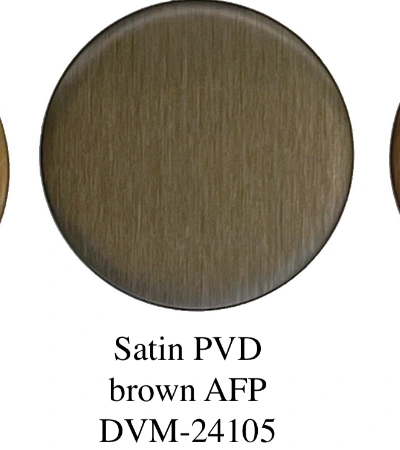

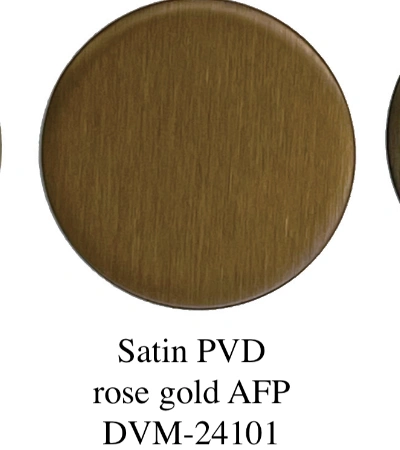

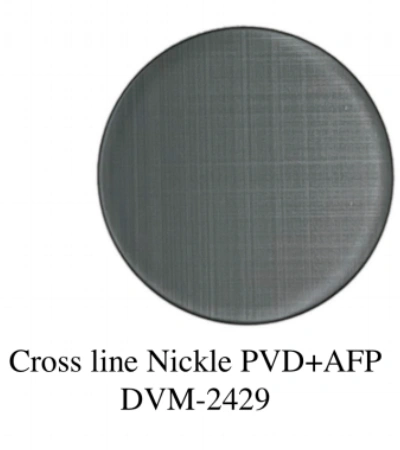

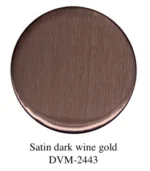

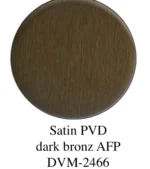

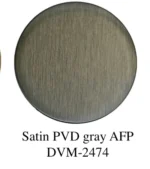

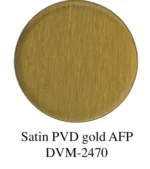

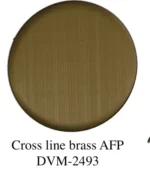

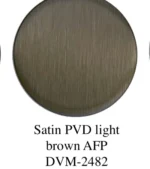

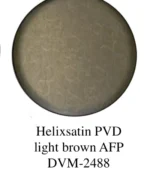

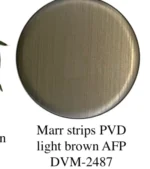

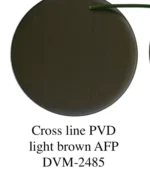

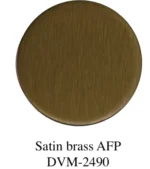

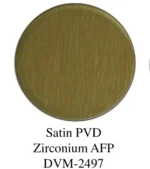

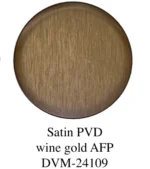

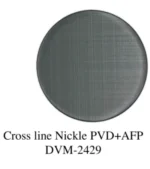

- Optional Coatings:

- Anti-fingerprint or PVD color coatings can be applied for additional protection and aesthetic appeal.

- Quality Inspection: Each sheet undergoes rigorous inspection for surface uniformity, texture consistency, and overall quality.

Characteristics

- Elegant Appearance: Brushed and matt finishes provide a refined and contemporary look, suitable for both modern and classic designs.

- Durability: Resistant to scratches and fingerprints, making it ideal for high-traffic or frequently used areas.

- Corrosion Resistance: Stainless steel’s natural rust resistance ensures long-lasting performance, even in challenging environments.

- Low Maintenance: The textured surface hides smudges and fingerprints, making it easy to clean and maintain.

- Versatility: Widely used for kitchen appliances, elevator interiors, wall cladding, furniture, signage, and architectural projects.

- Customizable: Available in various grades, finishes, and thicknesses to meet specific project requirements.