Materials

- SS 304: Known for its excellent corrosion resistance, durability, and versatile applications in various industries.

- SS 316L: Offers superior corrosion resistance, especially against chlorides, making it ideal for marine and chemical environments.

- SS 201: A cost-effective alternative with good corrosion resistance and high tensile strength, commonly used in decorative applications.

Processing

- Material Selection: High-quality stainless steel (SS 304, SS 316L, SS 201) is chosen to ensure optimal performance and durability.

- Surface Grinding: Initial surface preparation removes oxide layers, scratches, and imperfections, providing a smooth base for polishing.

- Polishing Techniques:

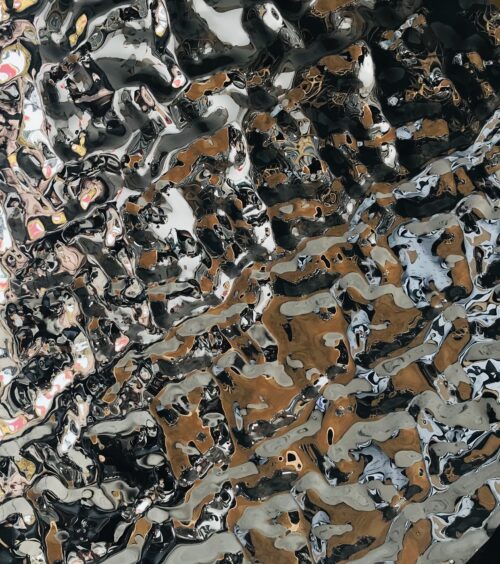

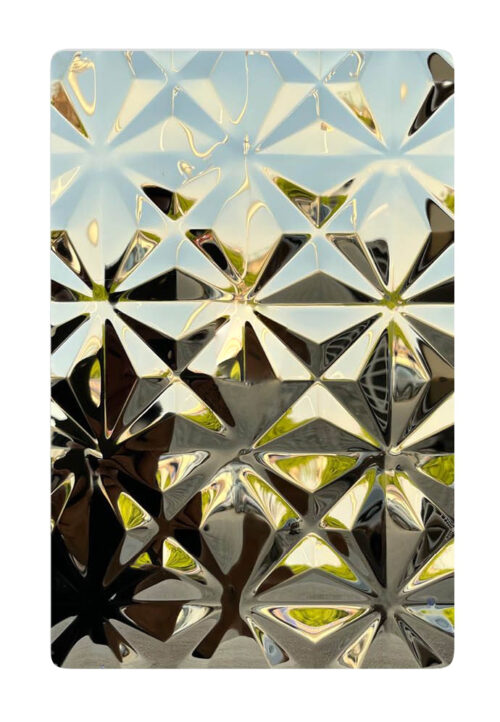

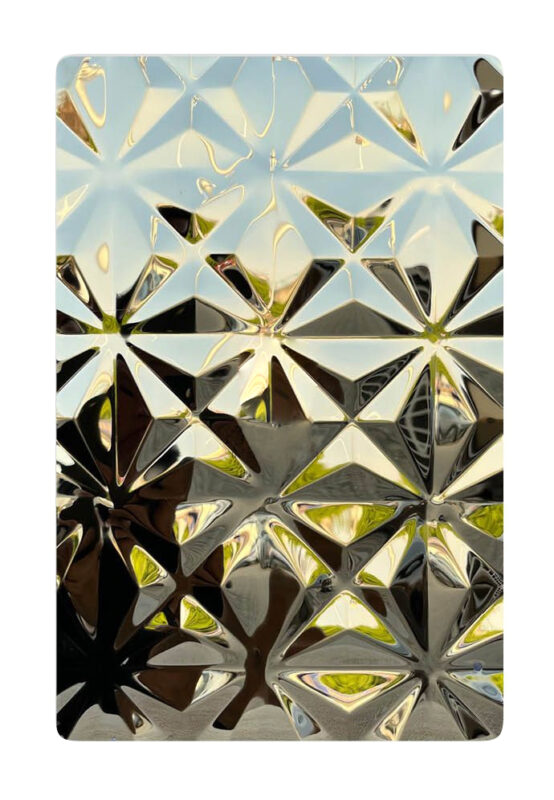

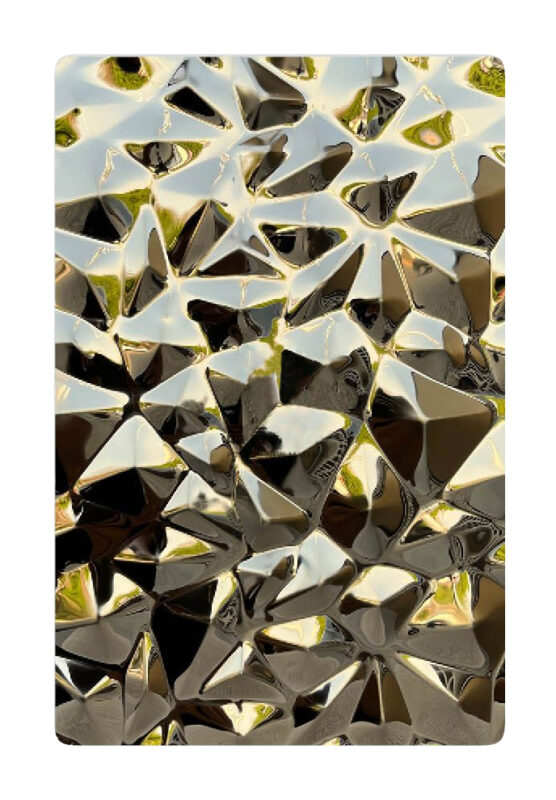

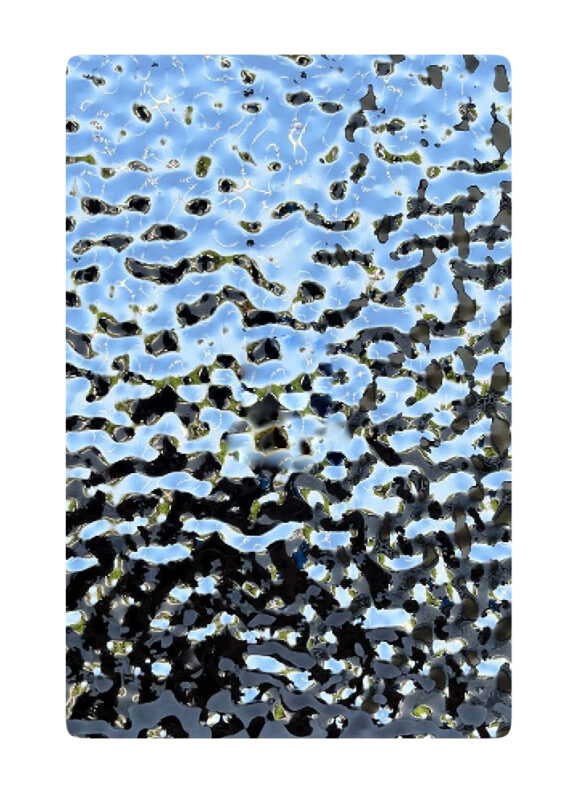

- Mechanical Polishing: Gradual grinding using abrasive belts or polishing wheels to achieve desired finishes (e.g., No.4 satin, No.8 mirror).

- Electropolishing: Enhances surface smoothness and gloss through electrochemical processes, improving corrosion resistance.

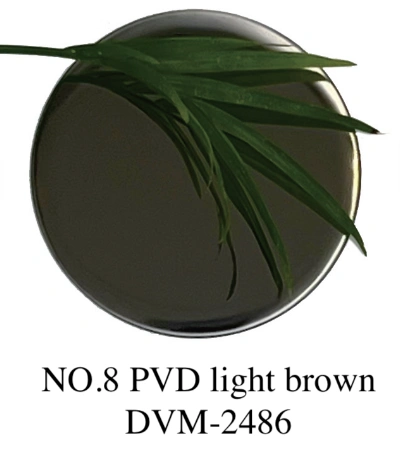

- Finishing Process: Options include anti-fingerprint coatings or other surface treatments to enhance cleanliness and durability.

- Quality Inspection: Thickness, surface smoothness, and gloss are thoroughly inspected to meet industry standards and client requirements.

Characteristics

- Aesthetic Appeal: Smooth and visually appealing surfaces suitable for decorative and industrial applications.

- Corrosion Resistance: Enhanced protection against rust and oxidation, even in humid or corrosive environments.

- Durability: High resistance to wear and impact, ensuring long service life and reduced maintenance costs.

- Easy Maintenance: Polished surfaces are easy to clean, resistant to fingerprints, and ideal for hygiene-sensitive applications.

- Customizability: Available in various finishes and textures, tailored to specific client needs.