Materials

- SS 304: Offers excellent corrosion resistance and durability, widely used for decorative and industrial purposes.

- SS 316L: Known for its superior resistance to corrosion and chemicals, suitable for demanding environments.

- SS 201: A budget-friendly option with good mechanical strength, ideal for decorative applications.

Processing

- Material Preparation: High-quality stainless steel sheets (SS 304, SS 316L, SS 201) are selected for embossing based on the application requirements.

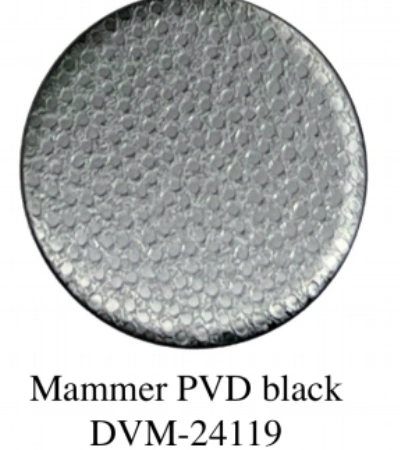

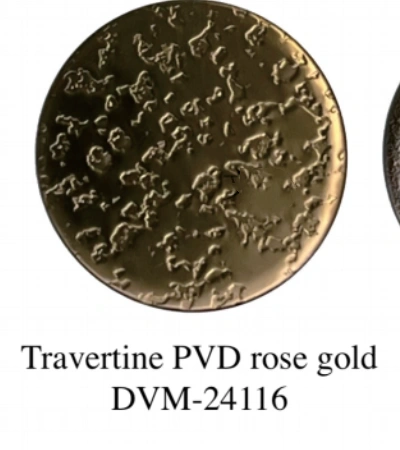

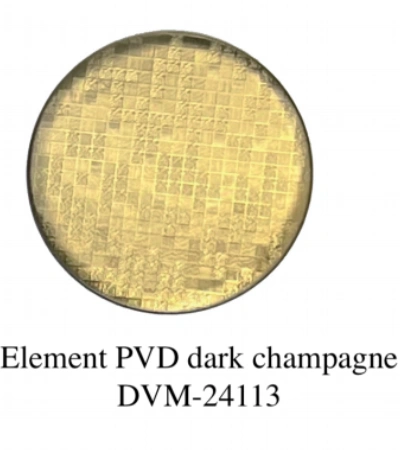

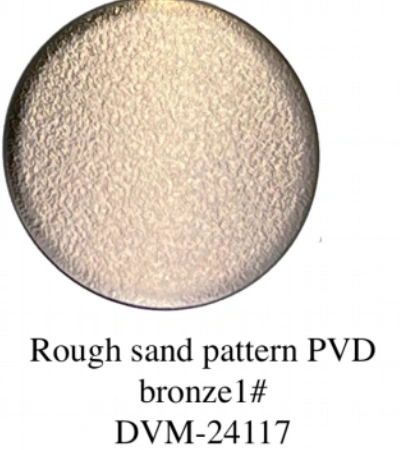

- Pattern Design: Custom designs are created using advanced software, including geometric, floral, and textured patterns.

- Embossing Process:

- Stainless steel sheets are passed through rollers or stamping machines with pre-designed molds.

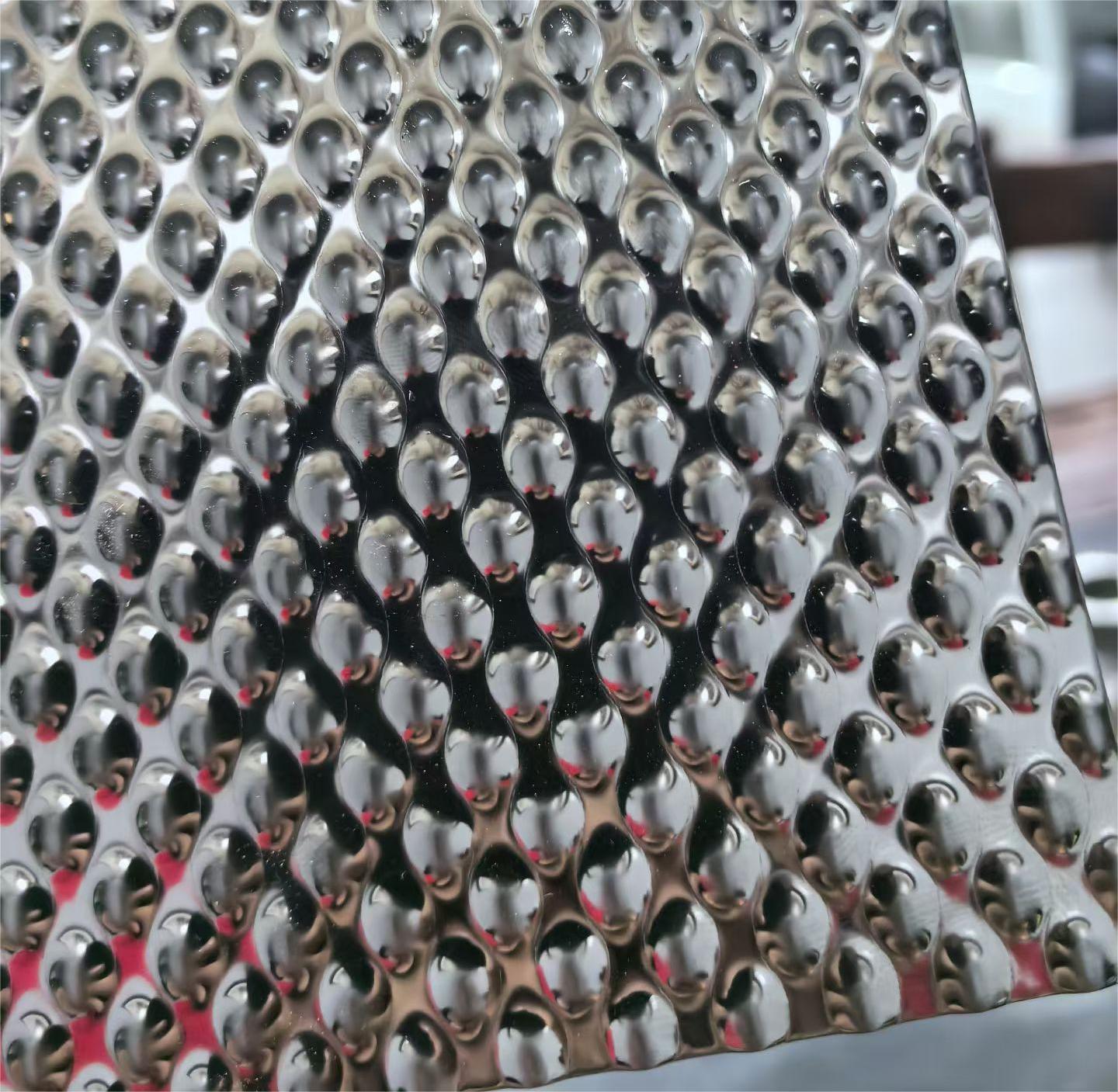

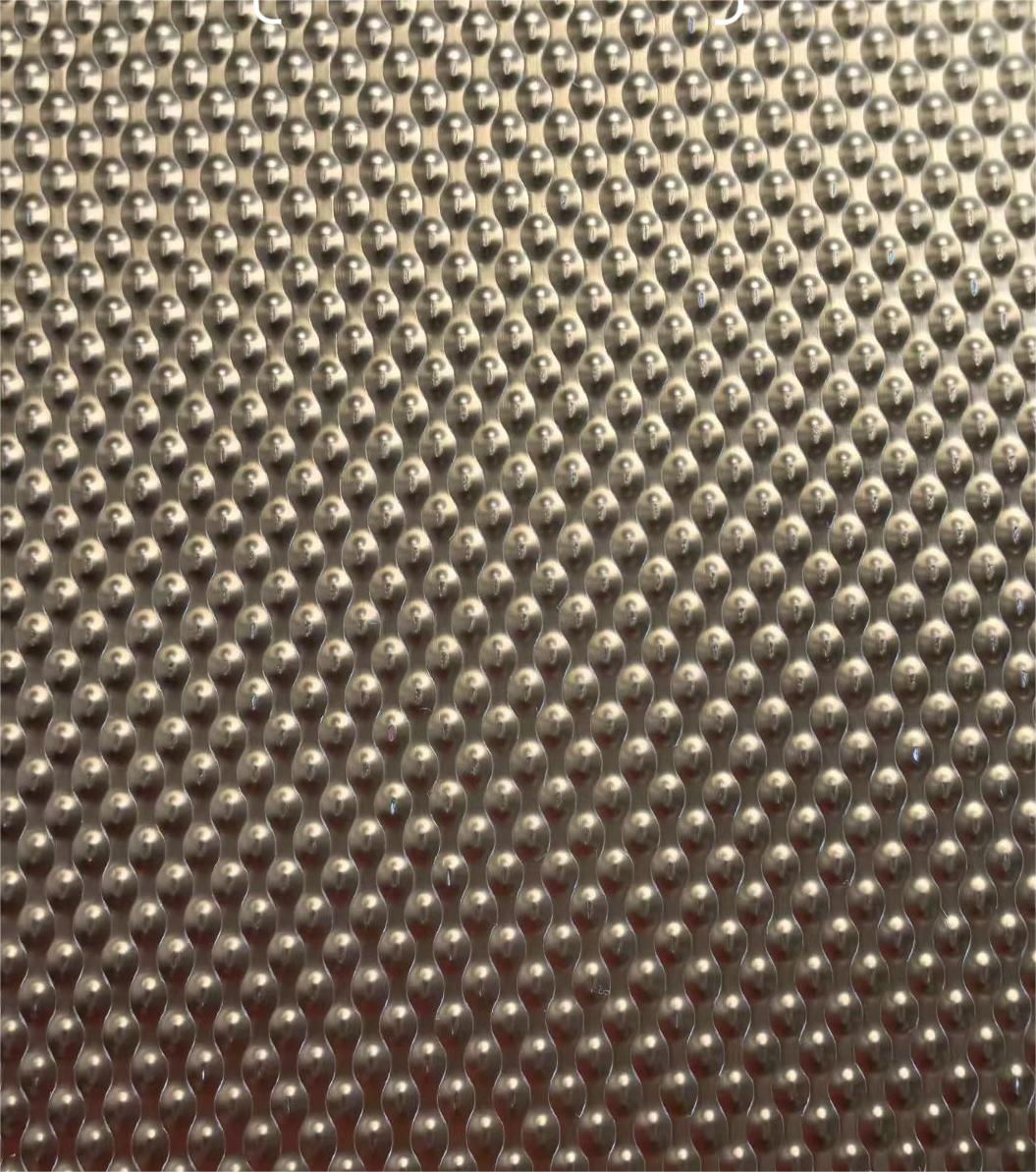

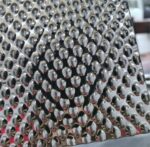

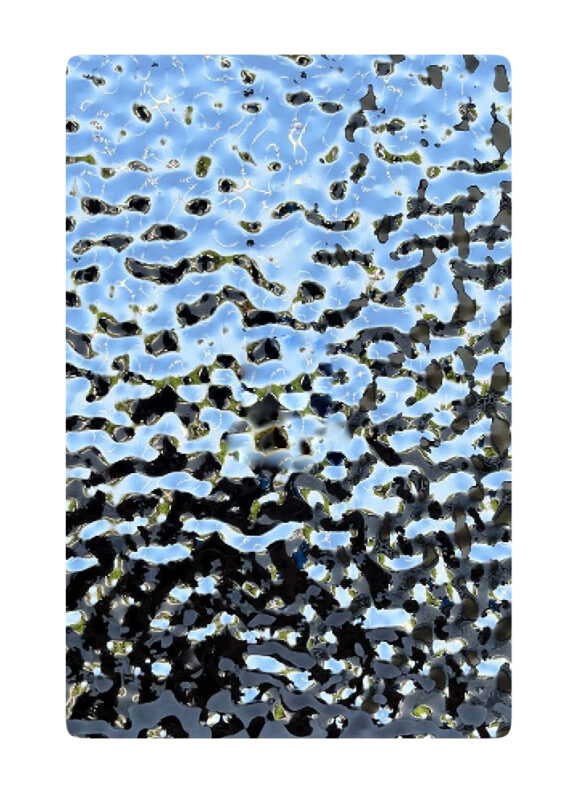

- The embossing process creates a three-dimensional raised pattern, adding depth and texture to the surface.

- Surface Finishing:

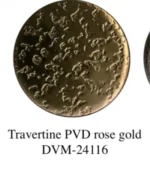

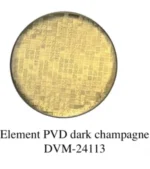

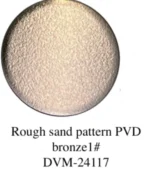

- Optional finishes include matte, satin, mirror, or color coatings (e.g., PVD).

- Anti-fingerprint or protective coatings can be applied to enhance durability and ease of maintenance.

- Quality Inspection: Each sheet undergoes strict inspections to ensure pattern uniformity, depth precision, and surface quality.

Characteristics

- Enhanced Aesthetic Appeal: Embossed patterns create a unique and visually striking appearance, perfect for decorative applications.

- Durability: The embossed surface provides increased resistance to scratches and wear, extending the product’s lifespan.

- Slip Resistance: Embossed textures improve grip, making them suitable for flooring and wall cladding in high-traffic areas.

- Corrosion Resistance: Made from stainless steel, these sheets are naturally resistant to rust and oxidation, ensuring longevity even in challenging environments.

- Versatility: Widely used for elevator interiors, wall panels, ceilings, signage, furniture, and decorative cladding in commercial and residential spaces.

- Customizability: Available in various patterns, sizes, and finishes to meet diverse design and functional needs.