Materials

- SS 304: Known for its excellent corrosion resistance and versatility, suitable for decorative and functional applications.

- SS 316L: Offers enhanced corrosion resistance, particularly in harsh or marine environments.

- SS 201: A cost-effective option with good strength and aesthetic appeal, commonly used for decorative purposes.

Processing

- Material Preparation: High-quality stainless steel sheets (SS 304, SS 316L, SS 201) are selected based on client requirements.

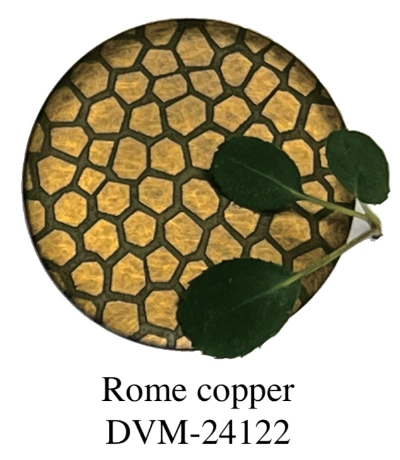

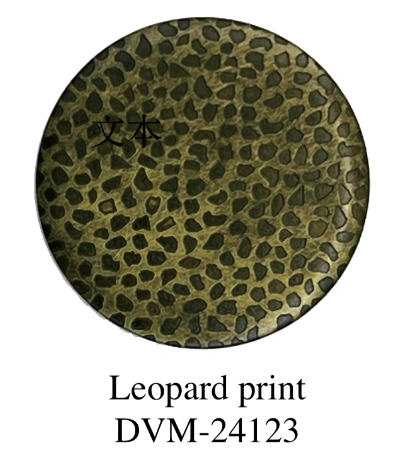

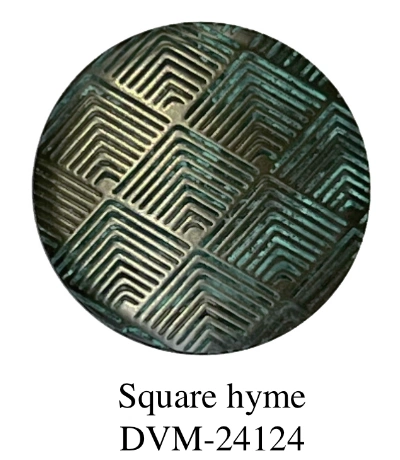

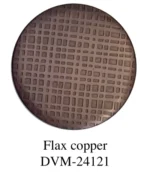

- Design Customization: Patterns, logos, or textures are created using specialized software to ensure precise designs.

- Masking: Protective layers are applied to areas of the sheet that are not to be etched, ensuring design accuracy.

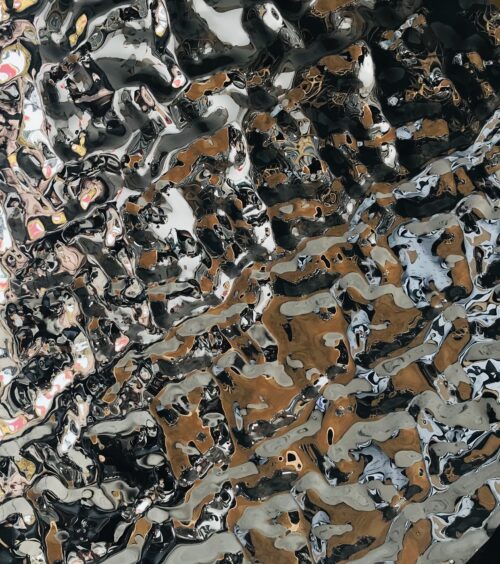

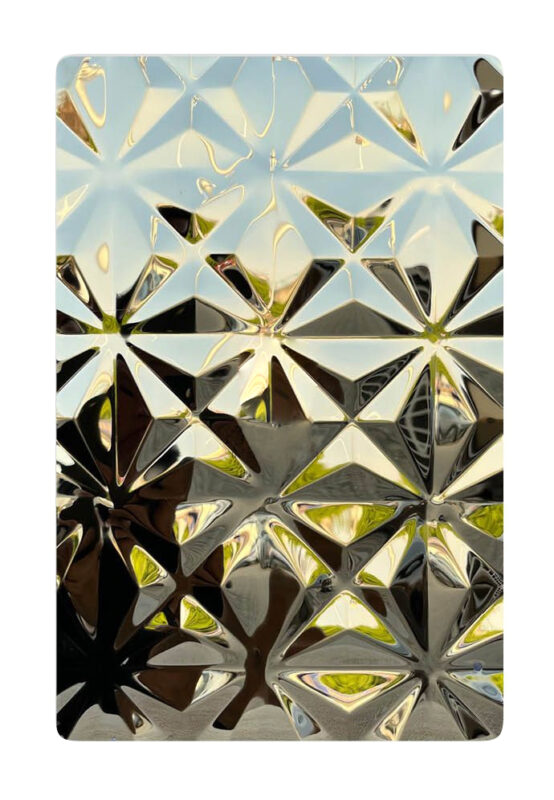

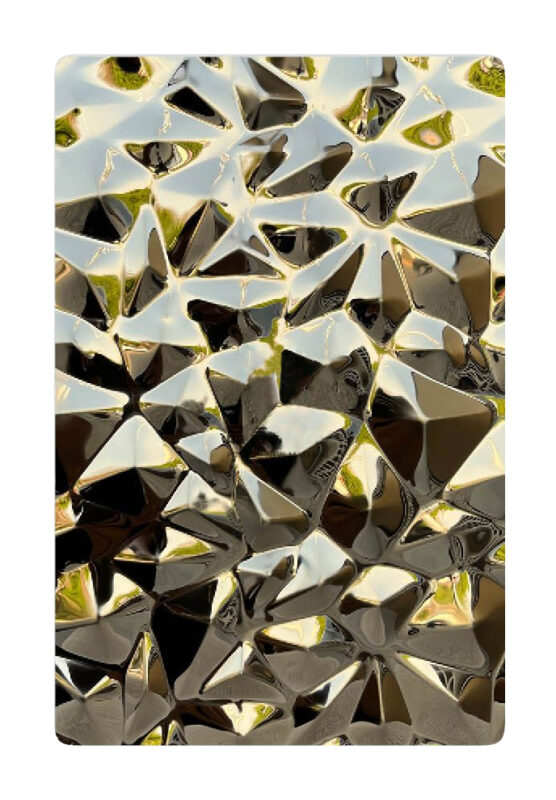

- Etching Process: Chemical solutions are used to etch the exposed areas, creating a permanent, textured pattern on the surface.

- Polishing and Finishing:

- Mirror or satin finishes can be applied to enhance the etched design.

- Optional coatings such as PVD (Physical Vapor Deposition) or anti-fingerprint layers are available for additional protection and aesthetic value.

- Quality Control: Each sheet is inspected for pattern clarity, consistency, and surface quality to meet high standards.

Characteristics

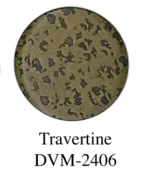

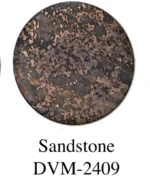

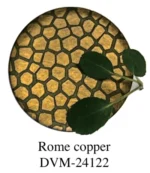

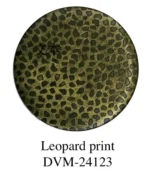

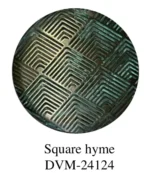

- Design Flexibility: Etching allows for highly customized patterns, including intricate details and unique textures.

- Durability: The etching process creates permanent designs that are resistant to wear, scratches, and fading.

- Corrosion Resistance: The stainless steel base ensures long-lasting resistance to rust and oxidation.

- Aesthetic Appeal: Suitable for luxury interior designs, elevator panels, signage, furniture, and decorative applications.

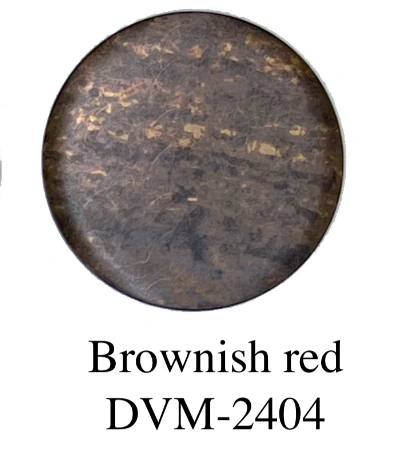

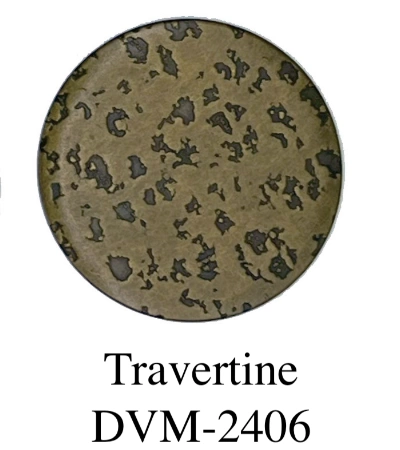

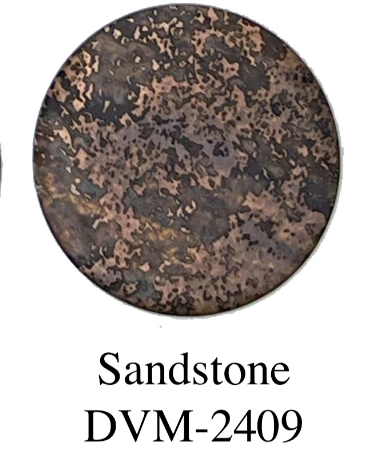

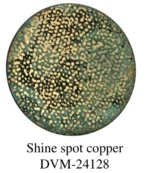

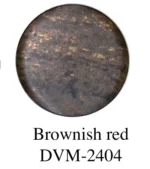

- Customizable Finishes: Available in a range of colors, textures, and surface treatments to suit diverse project needs.