Materials

- SS 304: Provides excellent corrosion resistance and durability, ideal for both decorative and functional uses.

- SS 316L: Known for its superior resistance to corrosion and chemicals, suitable for demanding environments.

- SS 201: A cost-effective option with good mechanical properties, commonly used in decorative applications.

Processing

- Material Selection: High-quality stainless steel sheets (SS 304, SS 316L, SS 201) are selected to ensure the desired performance and aesthetics.

- Surface Preparation: The stainless steel sheets are cleaned and pre-treated to remove any surface impurities, ensuring a flawless finish.

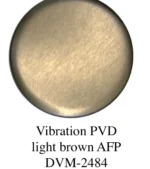

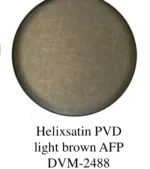

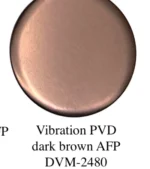

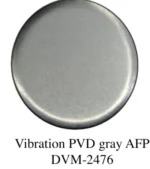

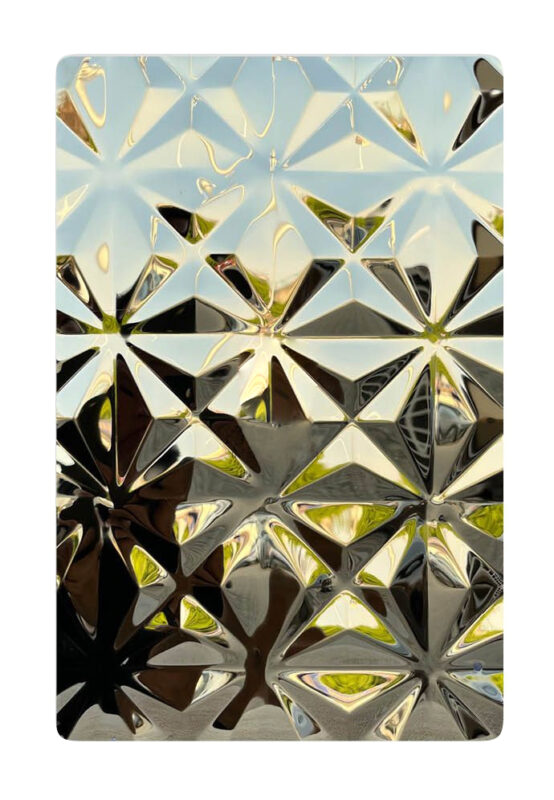

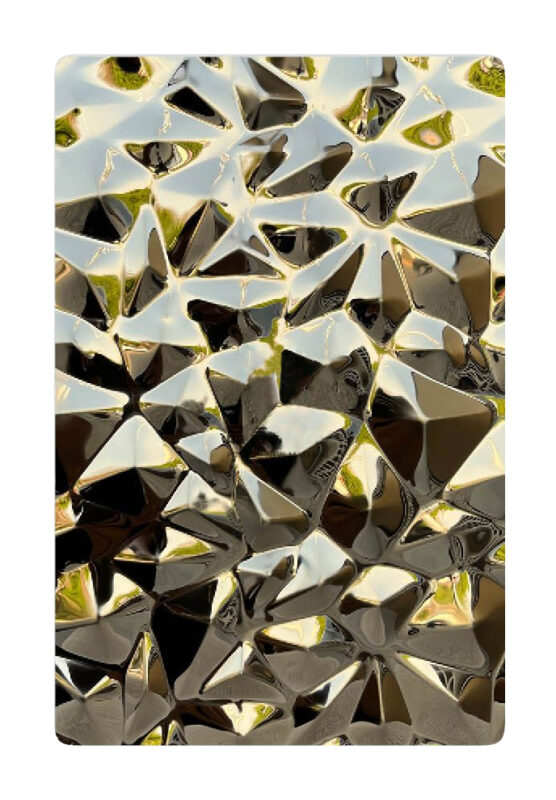

- Vibration Finishing:

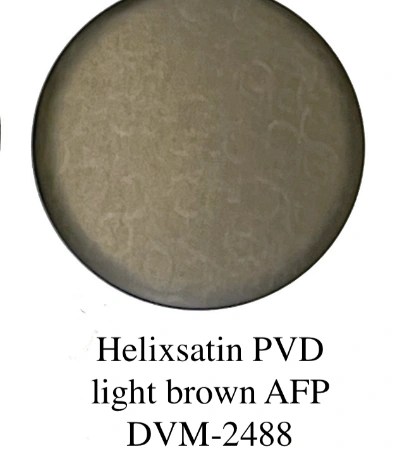

- Using specialized equipment, a random and uniform vibration pattern is applied to the surface.

- This process creates a non-directional, fine grain texture that enhances the aesthetic appeal and reduces visible scratches.

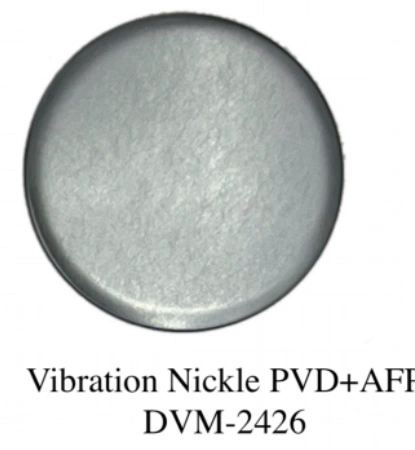

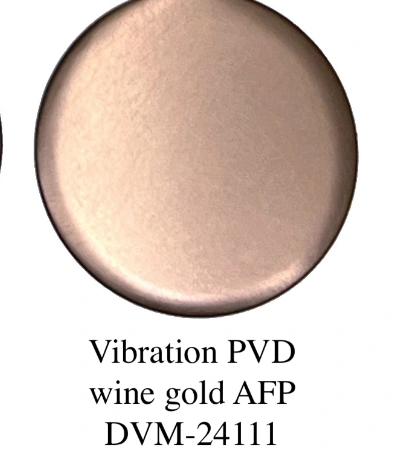

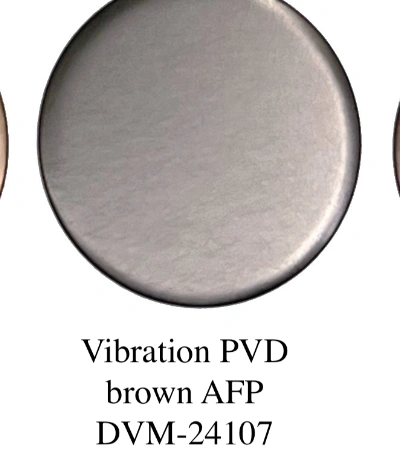

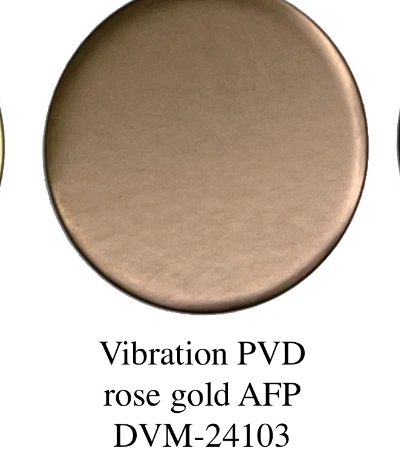

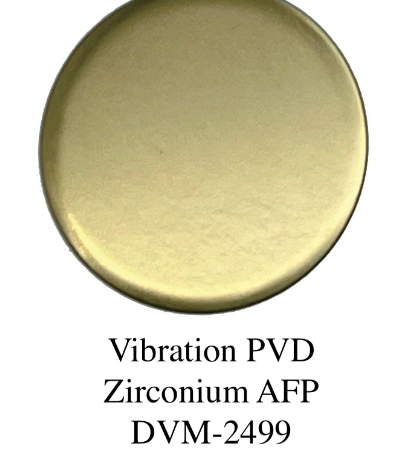

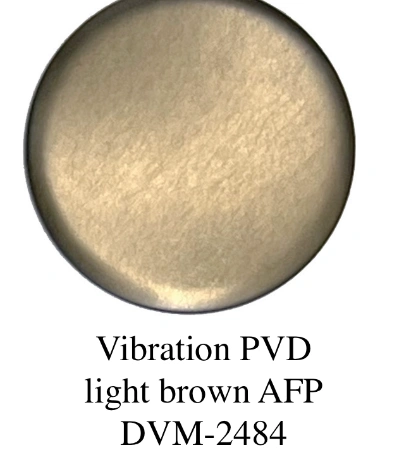

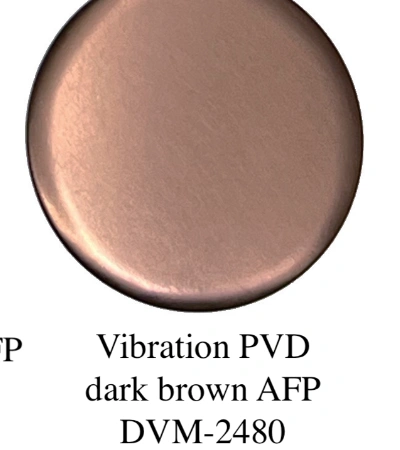

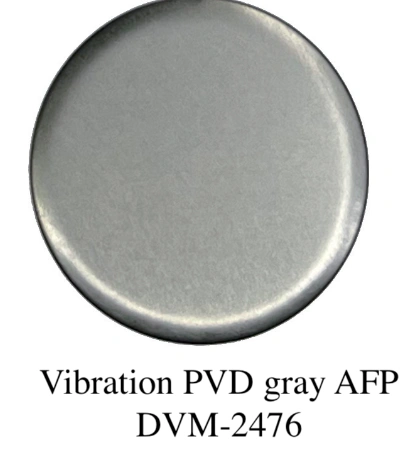

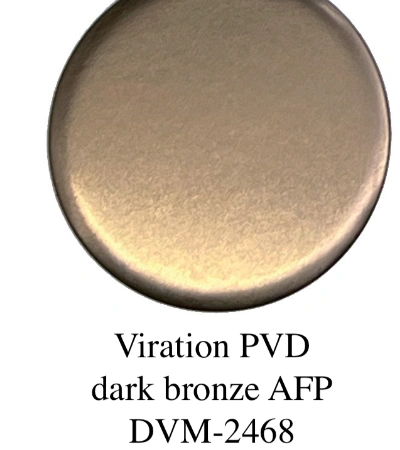

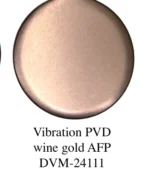

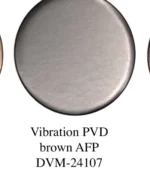

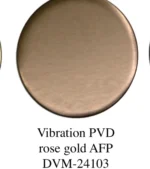

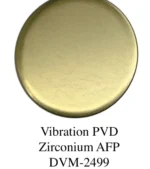

- Optional Surface Coating: Anti-fingerprint, PVD coatings, or protective layers can be added for improved durability and ease of maintenance.

- Quality Control: Each sheet is thoroughly inspected for uniformity, texture consistency, and surface quality to meet customer expectations.

Characteristics

- Non-Directional Finish: The vibration pattern creates a random, satin-like texture that is visually appealing and versatile.

- Durability: Resistant to scratches and wear, making it ideal for high-traffic or heavy-use areas.

- Corrosion Resistance: Maintains the rust-resistant properties of stainless steel, suitable for both indoor and outdoor applications.

- Low Maintenance: The texture hides fingerprints, smudges, and minor imperfections, making it easy to clean and maintain.

- Versatility: Commonly used for elevator interiors, kitchen surfaces, wall panels, furniture, and architectural designs.

- Customizable: Available in various thicknesses, sizes, and finishes to match diverse design and functional requirements.